Avalanche Diode DL171-400-6 (DA171-400-6) – Stud diode, 400A 600V

Avalanche Diode DL171-400-6AS ENERGITM is general purpose stud diode, also known as DA171-400-6. Average forward current IF(AV) – 400 ampere, repetitive peak forward and reverse blocking voltage VDRM/VRRM – 600V. Stud avalanche are designed to convert and control DC and AC currents. "Air-cooled heatsinks O series for stud devices" for avalanche diodes cooling are also available to order.

Polarity of the diode is determined by the symbol on the body. In forward polarity, the diode base is the anode, the flexible long lead is the cathode; in reverse polarity (symbol "X" in the marking), the flexible lead is the anode, the base is the cathode.

The peculiarity of avalanche diodes in comparison with power rectifier diodes is that they withstand significant overvoltages and restore their parameters after the voltage is removed.

Air and water heatsinks are used to cool the avalanche diodes. To provide reliable thermal and electrical contact with the heatsink a tightening torque Md must be observed during assembly. For better heat dissipation of diode during assembly, heat conducting paste is used (this is a recommendation and is not a prerequisite for installation).

Features: diodes are supplied in stud with flexible lead design. Avalanche diodes are used: as rectifier and demagnetizing diodes; to prevent the damaging effects of switching overvoltages; in low voltage rectifiers for welding and electroplating equipment; in uncontrolled or semi-controlled rectifier bridges; in industrial and transport generators

Avalanche Diodes AS ENERGITM have the following features: low static and dynamic losses, wide values of VDRM/VRRM, extensive experience of using the devices in various industries, range of voltages from 100 to 9000 V and amperages from 10 to 15000 A, high resistance to thermal and electric cycling, natural or forced air cooling.

The technical specifications and parameters of DL171-400-6 (DA171-400-6), datasheet PDF, outline drawing and dimensions are listed below.

Our company provides a quality guarantee for avalanche diodes of 2 years from the date of purchase. When supplying diodes, if necessary, we provide technical passport and certificate of conformity.

The final price for stud diodes depends on the voltage class, quantity, delivery terms, manufacturer, country of origin and form of payment.

General specifications of Stud (Flexible Lead) Avalanche Diodes DL171-400-6 (DA171-400-6) (400A 600V):

| Stud Diode specifications | DL171-400-6 (DA171-400-6) |

|

| Average forward current (Case temperature) | IF(AV) (TC) | 400 A (115ºC) |

| Repetitive pulsed closed state voltage; repetitive pulsed reverse voltage | VDRM/VRRM | 600 V |

| RMS forward current | IFRMS | 628 A |

| Surge forward current | IFSM | 12 kA |

| Peak forward voltage, max | VFM | 1.40 V |

| Peak forward current, max | IFM | 1256 A |

| Forward threshold voltage, max | VF(TO) | 0.75 V |

| Forward slope resistance, max | rT | 0.42 mΩ |

| Repetitive peak reverse current, max | IRRM | 35 mA |

| Temperature of p-n junction | Tvj max | 150 ºC |

| Thermal resistance, junction to case, max | Rth(j-c) | 0.080 ºC/W |

| Weight | W | 0.465 g |

| Recommended heatsinks | Heatsinks | O181, O281, OM105 |

| Package (Housing) | type | SD7 |

| Stud thread | - | M24 |

| Tightening torque | Md | 25-35 Nm |

| Datasheet | ||

Part Numbering Guide for Stud Avalanche Diode:

| DL | 171 | - | 400 | - | 6 |

| DL | – | Diode Avalanche (alternative marking "DA") |

| 171 | – | Diode type (stud type, flexible lead). |

| 400 | – | Average forward current IF(AV), Amp. |

| 6 | – | Voltage class VRRM / 100 (Nominal voltage – 600 V). |

High Power Semiconductors AS ENERGITM

Our company is engaged in the manufacturer and sale of wide range of power semiconductors (power thyristors, modules, rectifier diodes, avalanche, rotor and welding diodes, triacs etc.) currents up to 15000A and voltages to 9000V, and air and water heatsinks to them.

You can buy semiconductor devices in any volumes, and when ordering large lots, the price will be lower. We have earned the trust of customers and supply products all over the world.

For questions regarding the acquisition of Power Thyristors, Diodes, Modules send an email request to:

And we will provide you a commercial offer for delivery.

For a large number, we will provide an individual price!!!

We are open to manufacture products at our production facilities

according to your requests and technical task.

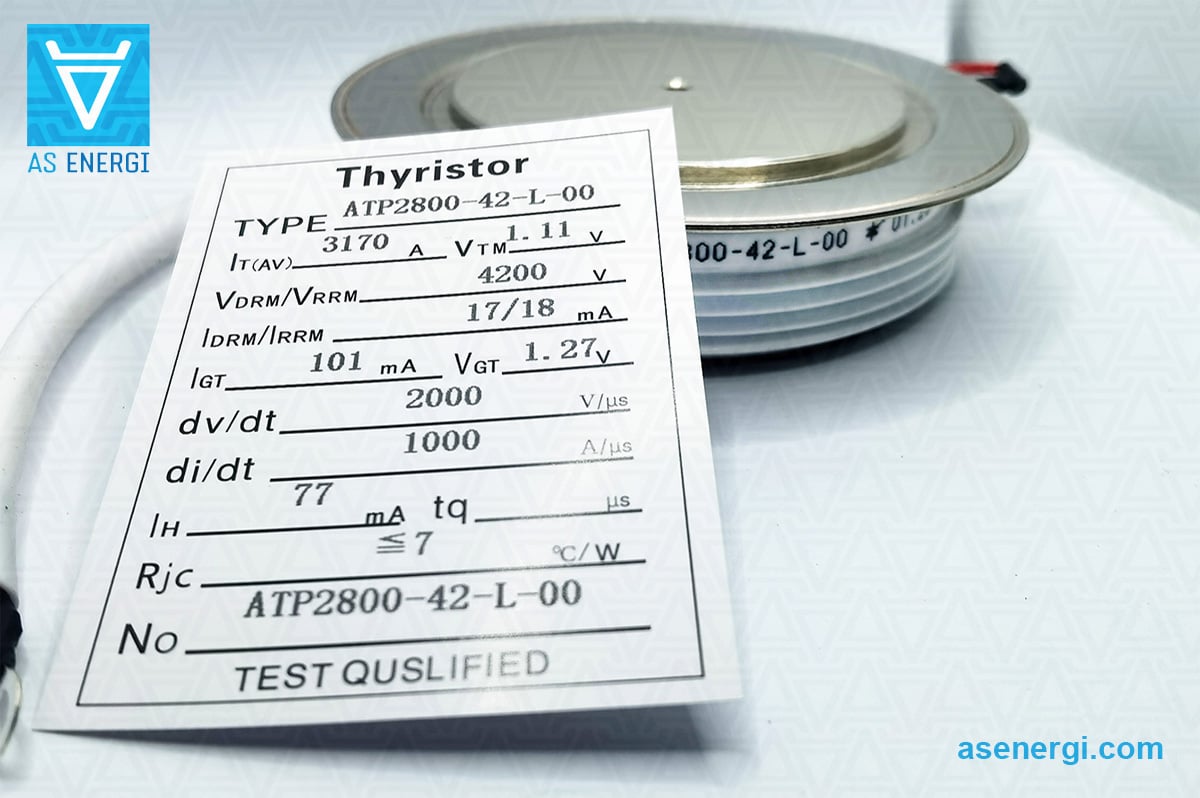

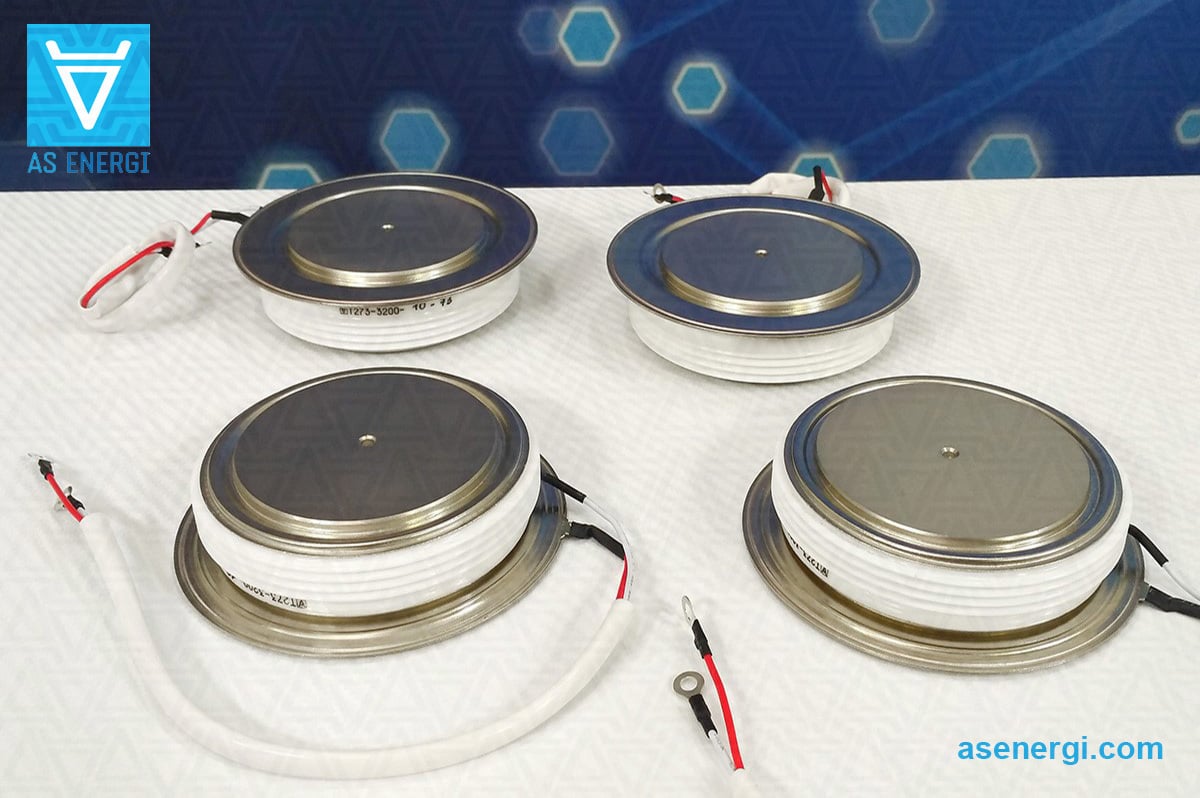

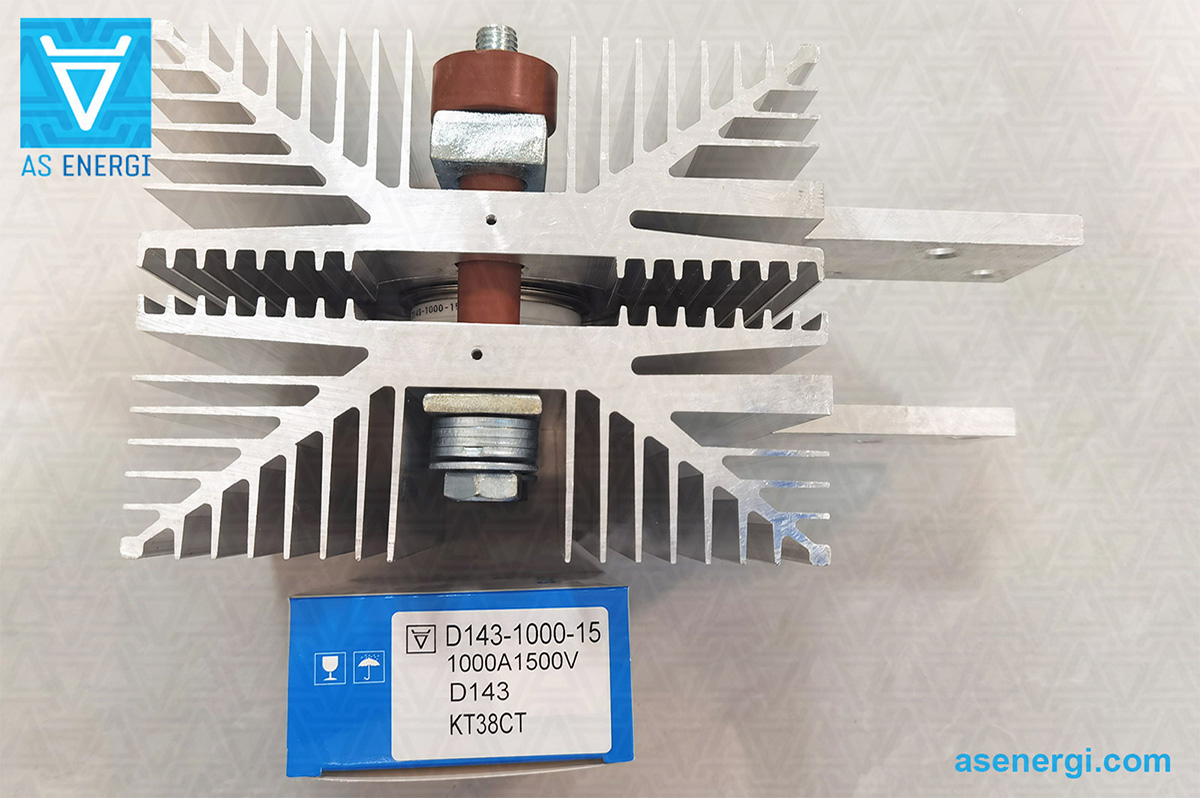

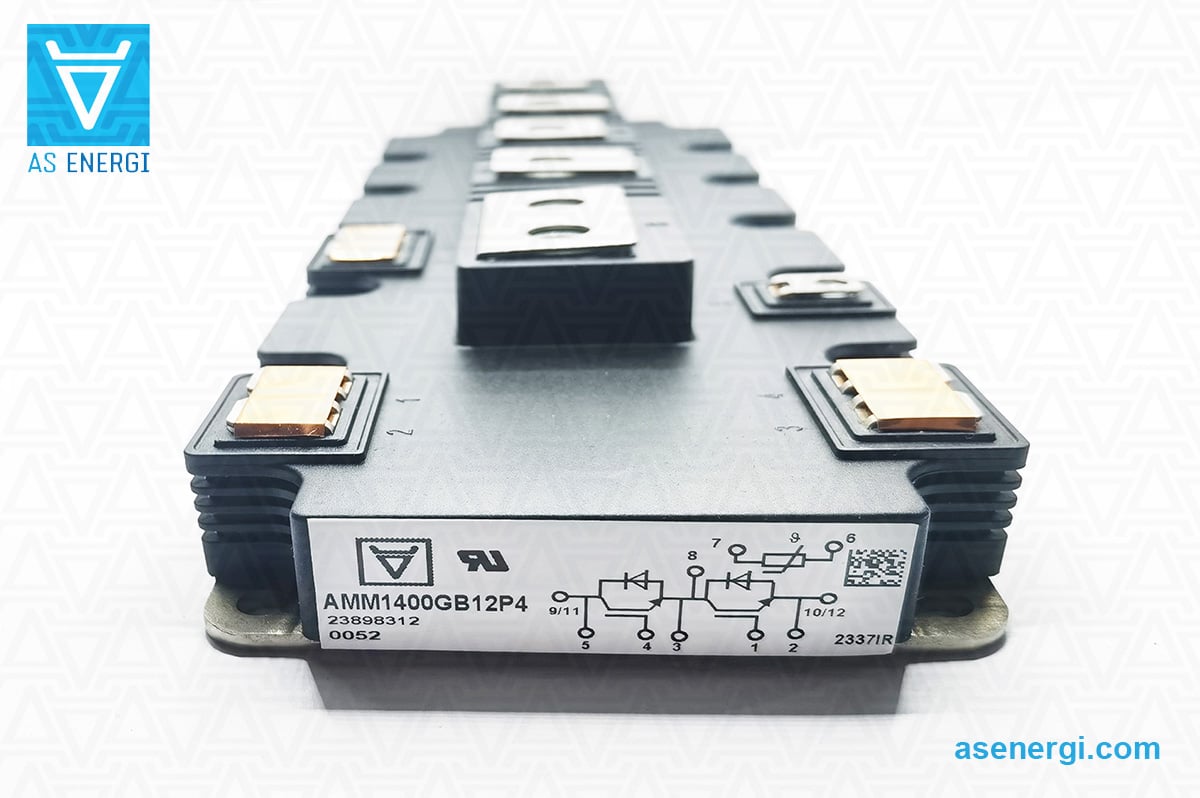

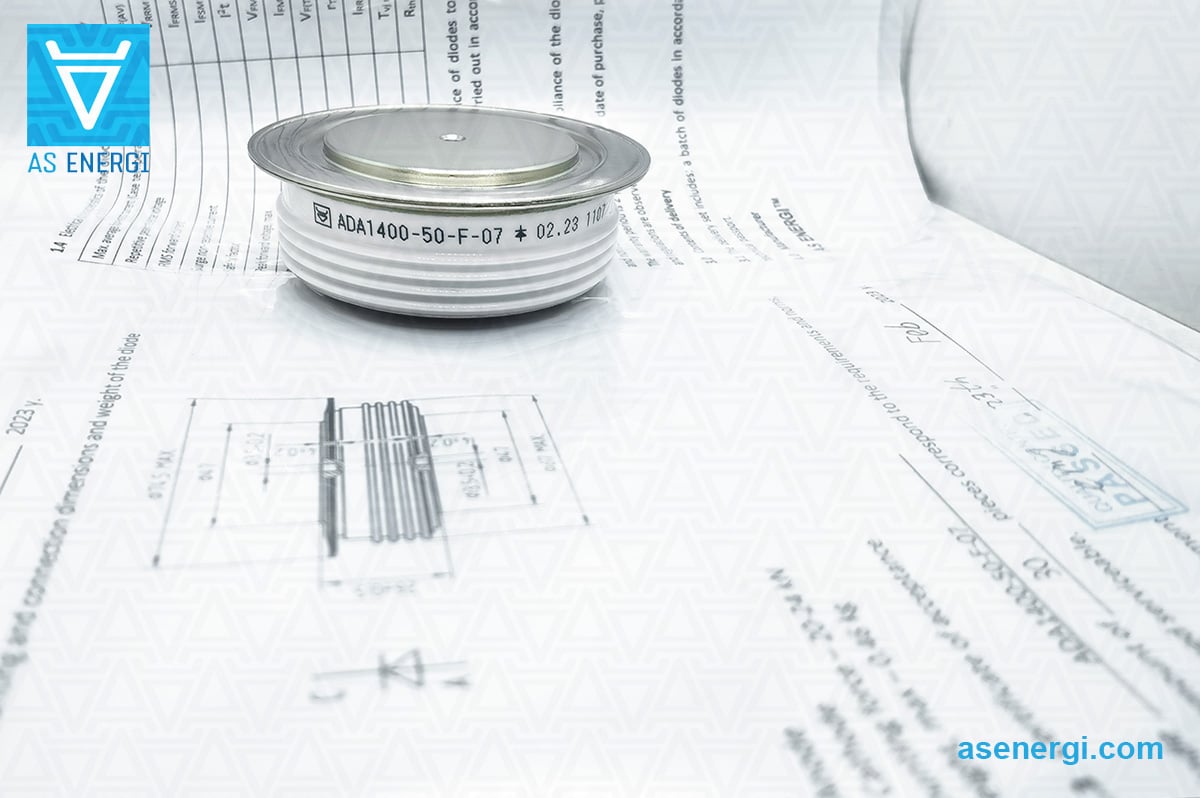

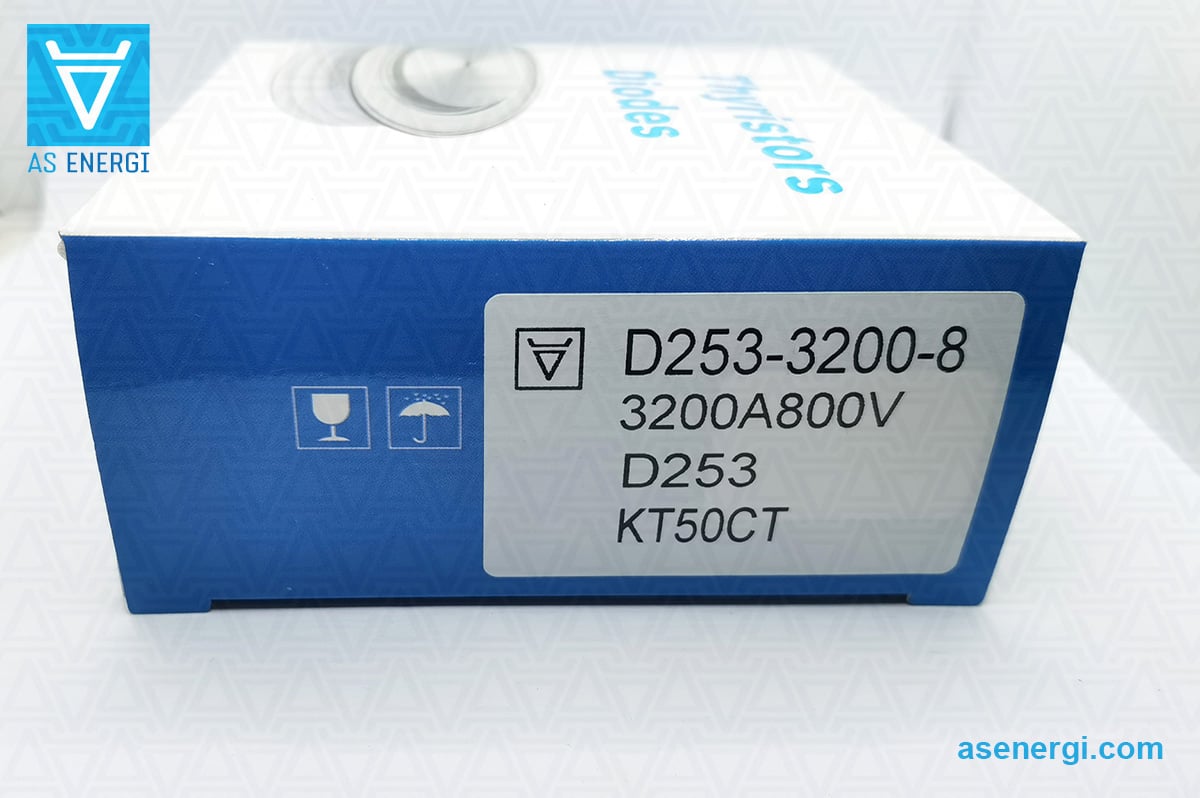

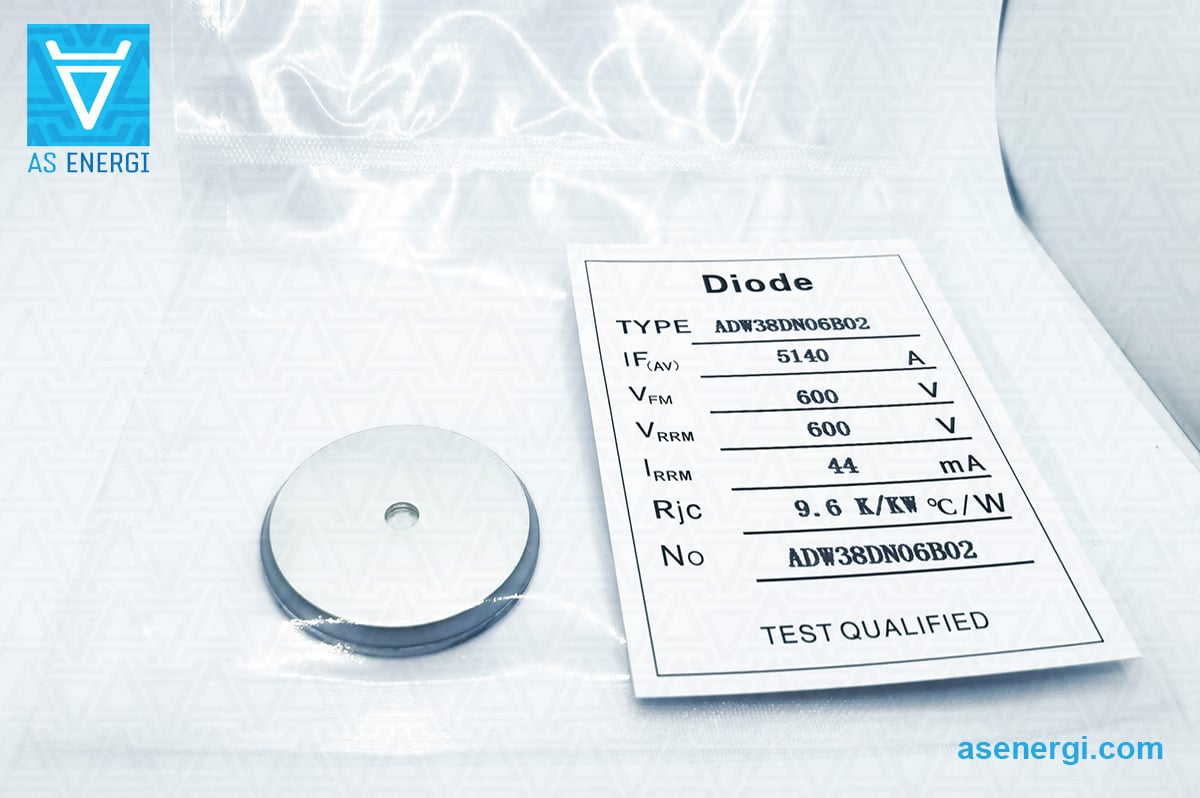

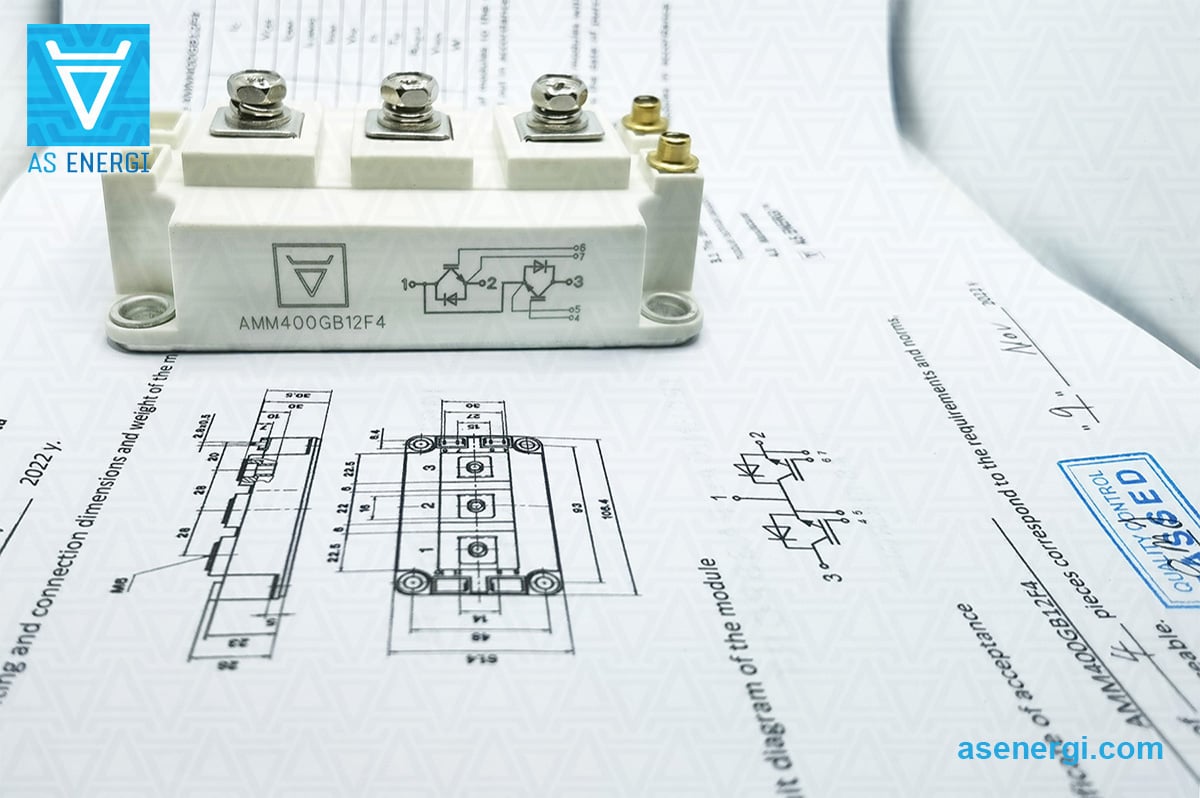

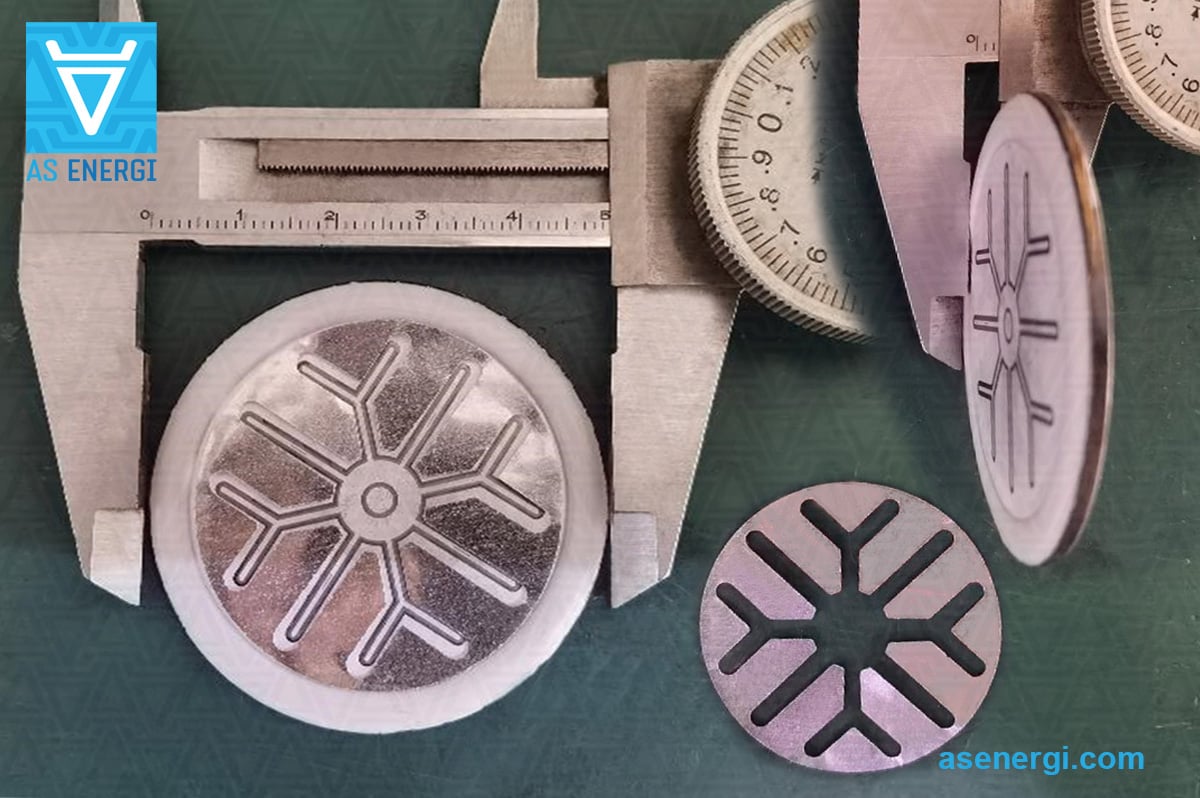

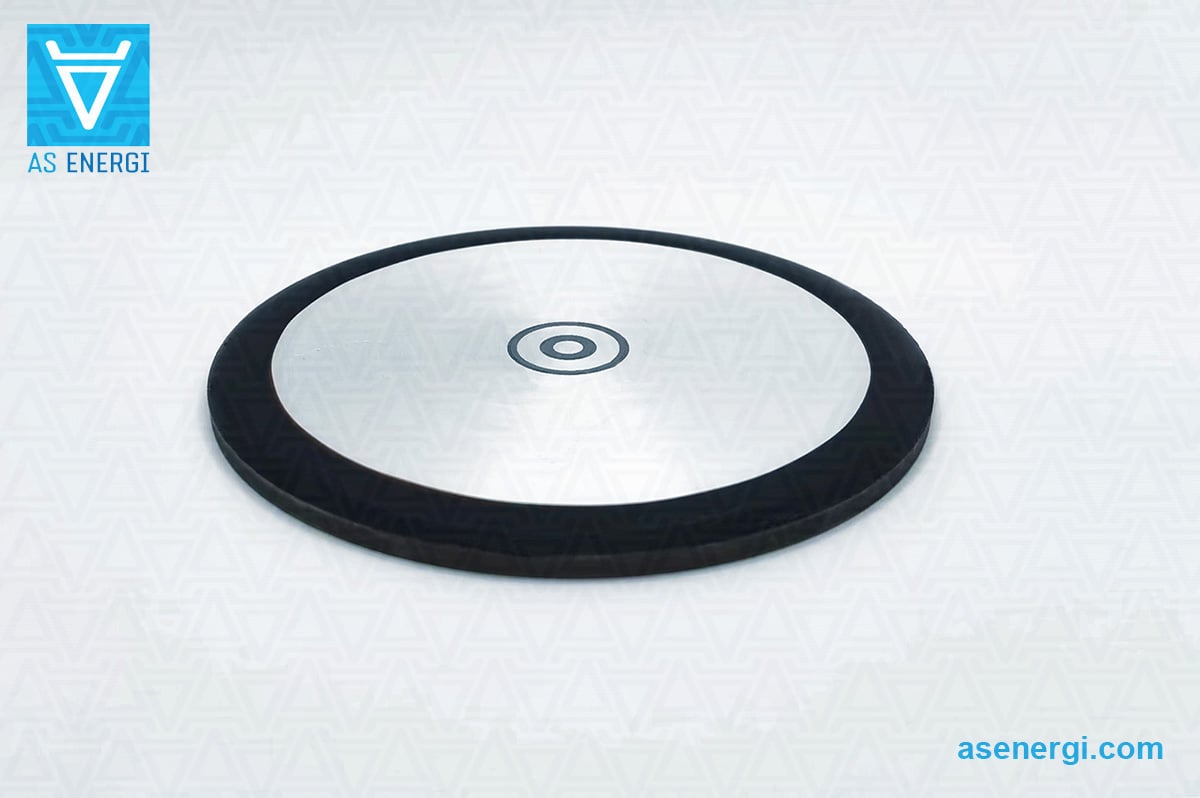

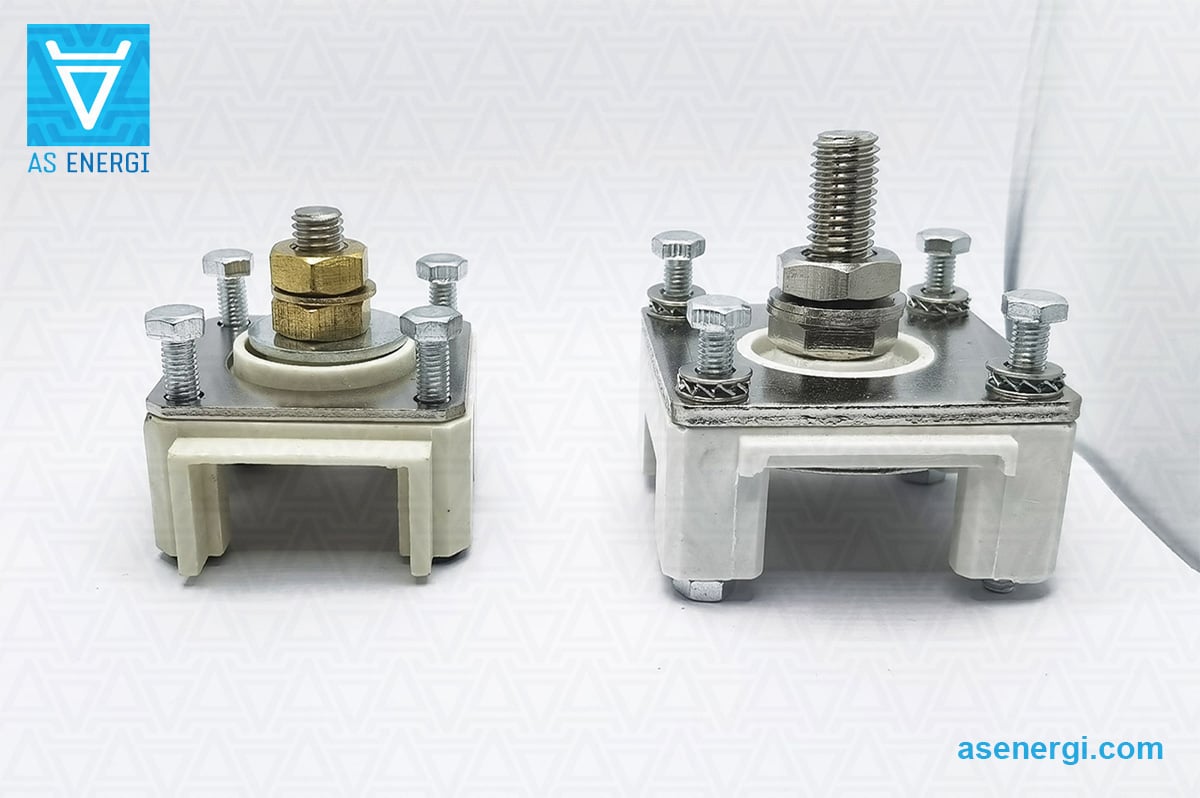

Photo Gallery

The photo gallery shows many different semiconductor devices, semiconductor chips and SCRs produced by AS ENERGITM, examples of test reports.

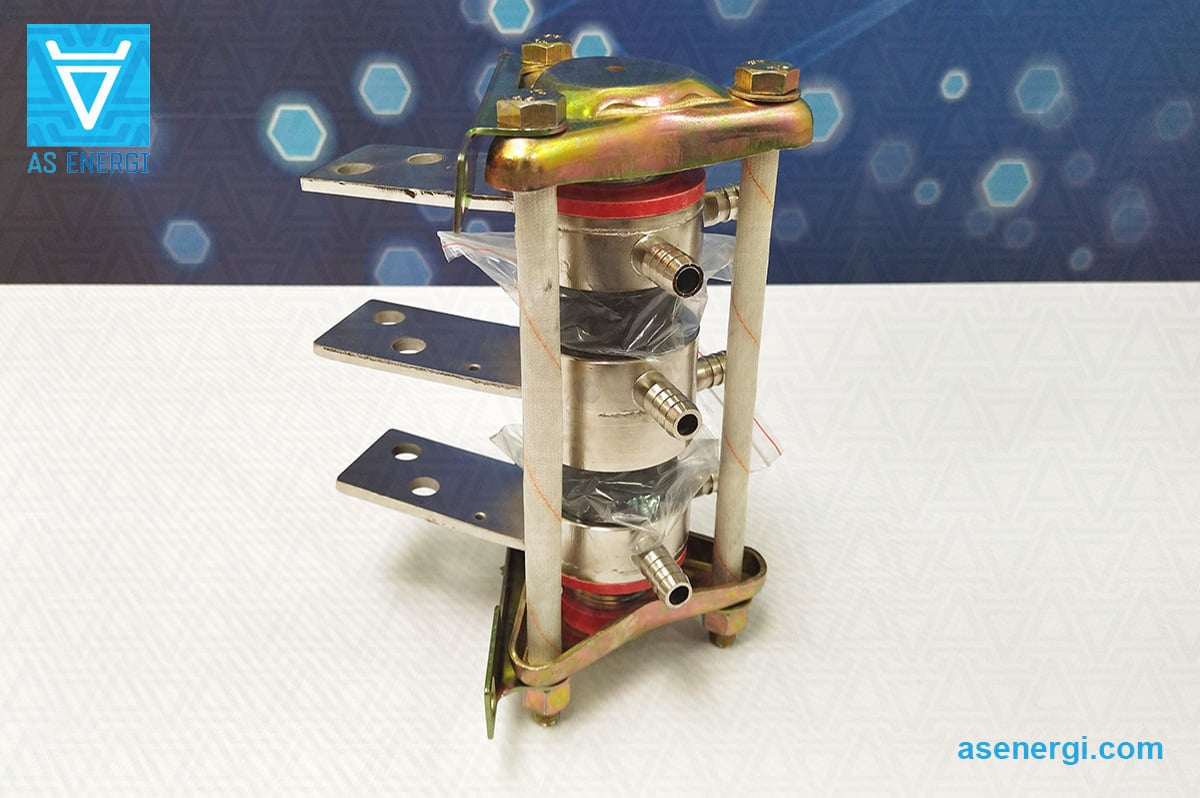

Heat sinks for power stud diodes:

Heat sinks (radiators) are used for cooling of power semiconductor devices in stud design.

Heat sinks of coolers are made of aluminum radiator profiles and do not require additional protective coating when used in various climatic conditions.

See for more information about heatsinks: "Air-cooled heatsinks for stud devices".

Installation recommendations for stud type power rectifier diodes:

The reliability of heat transfer and electrical contact between the mating surfaces of the diode and the cooler over the entire temperature range is ensured by appropriate torque.

Before assembly you should perform visual inspection (1) contact surfaces for mechanical damages and wipe (2), soaked with alcohol (toluene, gasoline, acetone).

To improve the parameters of heat transfer it is recommended to lubricate (3) a thin layer of silicone thermal conductive paste before the assembly, which is not a mandatory condition for installation.

After installation, the fasteners (nuts and washers) must be additionally secured against corrosion.

Why choose AS ENERGITM

Why choose AS ENERGITM

- Own production facilities, including semiconductor silicon chips production

- European brand - 100% quality, favorable price, short production terms

- Over 20 years of experience in the semiconductor industry

- Clients from more than 50 countries trust us

- 20000 items in the product line for currents from 10A to 15000A, voltages from 100V to 9000V

- We produce analogues of other manufacturers' products

- Guaranteed certified quality, warranty period of operation - 2 years

Quality Warranty

Our products are certified and correspond to international standards.

Our company provides a quality guarantee for products of 2 years.

We provide certificates of conformity, reliability reports, data sheets and technical passports at the request of the customer.

Each product is tested for the main parameters, and Test reports of the parameters for each product are provided.

Geography of partnership

AS ENERGITM company manufactures and supplies power semiconductors to more than 50 countries around the world.

Logistics and Delivery

We deliver our products all over the world with the services of logistics companies: DHL, TNT, UPS, EMS, Fedex, Aramex.

Products can be delivered by any means of transport: air, sea, rail and road.

AS ENERGITM Semiconductors Manufacturing

Our products range includes rectifier diodes, phase control thyristors in disc and stud design, avalanche diodes and thyristors, fast switching, high frequency thyristors, fast recovery, welding and rotor diodes, triacs, bridge rectifiers, power modules (thyristor, diode, thyristor-diode, IGBT), and air and water heatsinks to them.

Power diodes and thyristors are produced for currents from 10A to 15000A, voltage range from 100V to 9000V.

Power diode and thyristor modules are produced from 25A and up to 1250A, voltage range 400V - 4400V.

The range of power semiconductors also includes equivalent, replacement, analogue and alternative semiconductor devices of global manufacturers.

Featured Products:

DE

DE IT

IT