Water Cooling Heatsink SS series for thyristor & rectifier diode

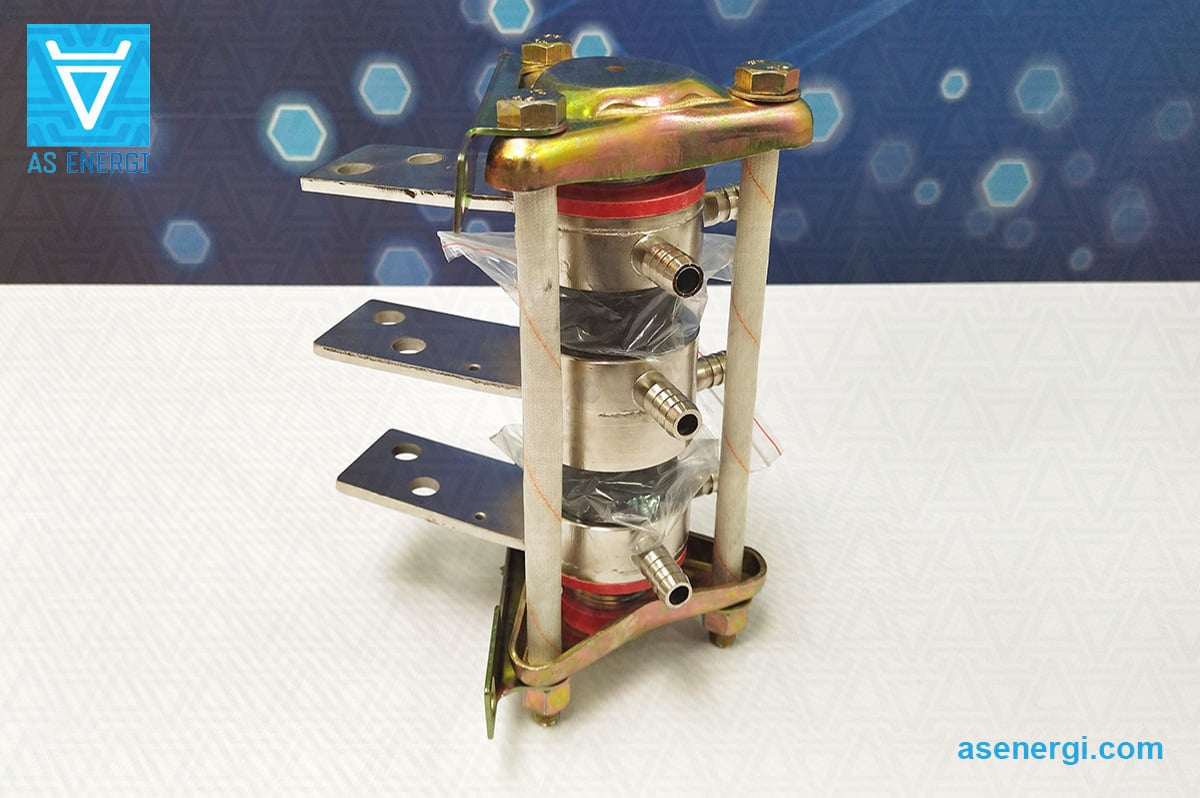

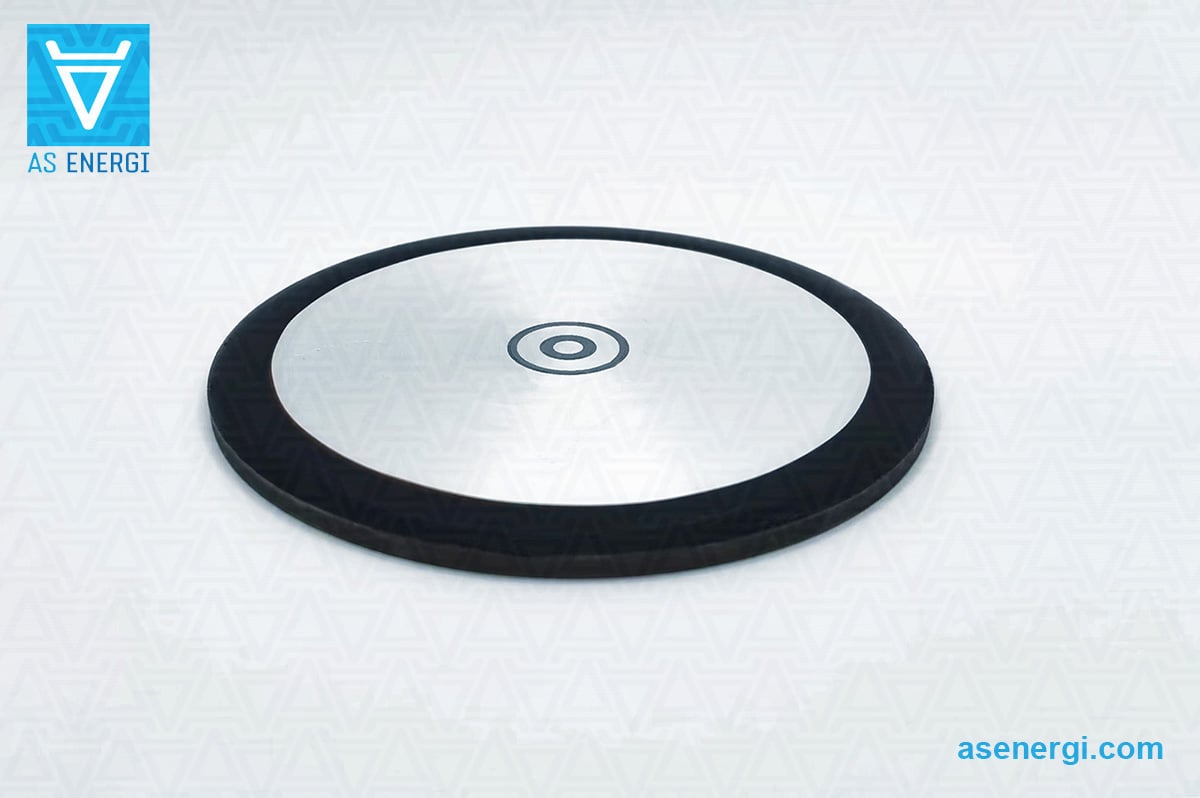

Water Cooling Heatsink SS series for cooling power SCR thyristors and diodes in disc design during their operation.

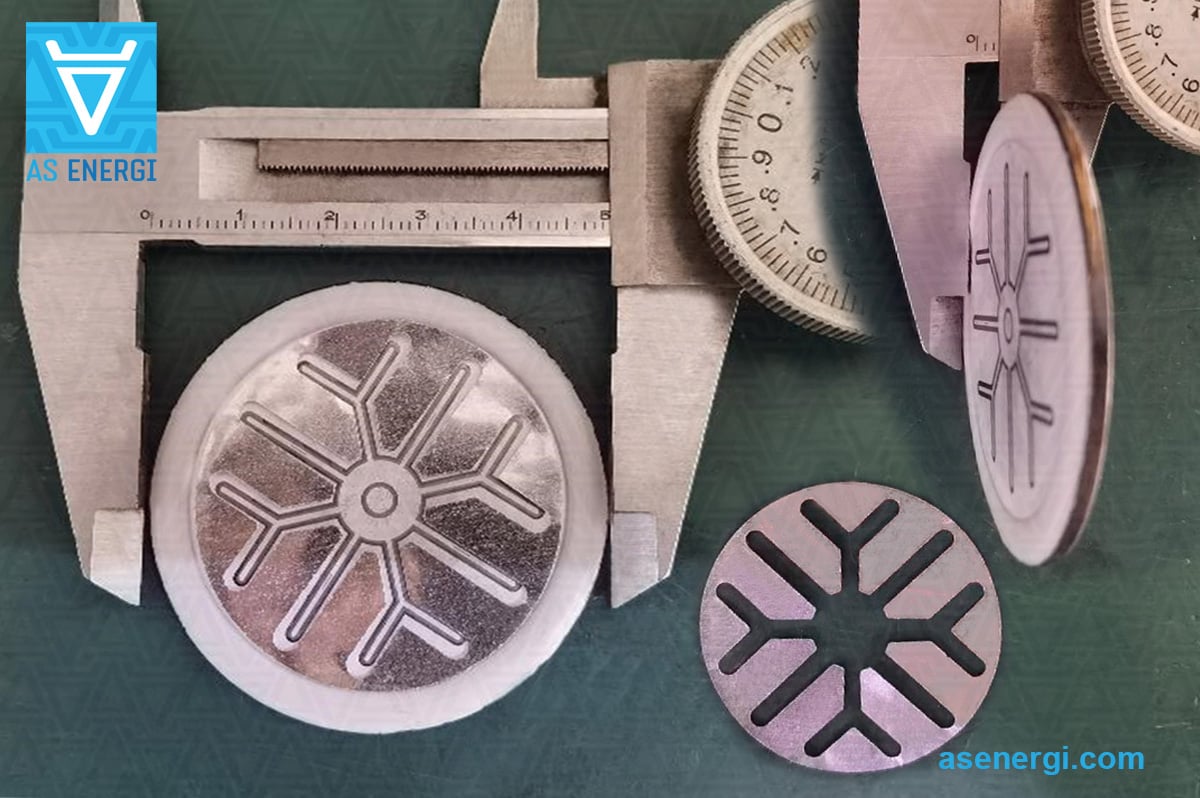

Features: disc device water cooling; high efficient heat transfer waterway design; low thermal resistance; multiple structures and installation modes.

Technical passport for water cooling heatsinks

Installation recommendations.

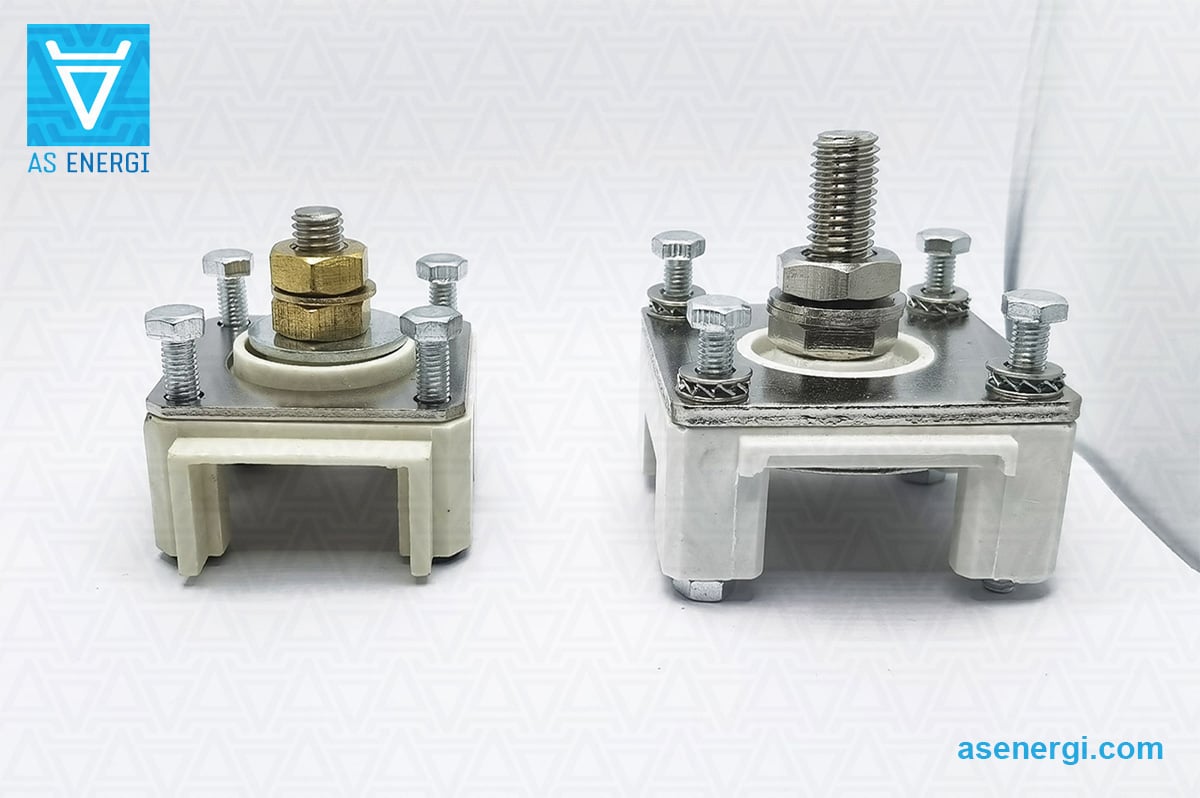

Shown in figure, the cathode side toward the studs side of device.

Ensure the device parallel to the mesa heat sink fully and concentric.

Pressure must uniform, the pressure can be calculated according to the mesa size.

Three fastening nuts firstly must tighten and flatten the butterfly spring.

When assembling, the necessary clamping force specific for each type of thyristor / diode package must be provided.

Types of Water Cooling Heatsinks: SS11, SS12, SS13, SS14, SS15, SS16, SS24, SS25 – monopipe water cooling heat sink for single device; SS11BL, SS12BL, SS13BL, SS14BL, SS15BL, SS16BL, SS24BL, SS25BL – doublepipe water cooling heat sink for double devices.

Specifications and parameters, dimensions, drawings of water cooling heat sink (radiator) are listed below.

Our company provides a quality guarantee for water cooling heatsink SS series of 2 years from the date of purchase. When supplying heatsinks, if necessary, we provide technical passport.

The final price of water cooling heatsink SS series depends on the quantity, delivery terms, manufacturer, country of origin and form of payment.

General specifications of Water Cooling Heatsink SS series for thyristors & rectifier diodes

| Heatsink | Plate surface diameter | Applicable case | Mounting force | Thermal resistance | Applicable SCR | |

| Plate surface | Max O.D. case | kN | °C/W | |||

| SS11, SS11BL | Ø23, Ø27 | Ø24-Ø27 | ≤ Ø40 | 3.3-20 | 0.026 | 200A - 800A |

| SS12, SS12BL | Ø32-Ø41 | Ø32-Ø41 | ≤ Ø66 | 5.5-25 | 0.018 | 200A - 800A |

| SS13, SS13BL | Ø68 | Ø40-Ø65 | ≤ Ø90 | 15-34 | 0.015 | 500A - 2500A |

| SS14, SS14BL | Ø84 | Ø50-Ø73 | ≤ Ø110 | 18-47 | 0.013 | 800A - 2500A |

| SS15, SS15BL | Ø100 | Ø73-Ø100 | ≤ Ø160 | 60-70 | 0.011 | 2000A - 3000A |

| SS16, SS16BL | Ø108 | Ø73-Ø100 | ≤ Ø200 | 60-100 | 0.008 | 3000A - 6500A |

| SS24, SS24BL | Ø84 | Ø50-Ø84 | ≤ Ø110 | 18-70 | 0.010 | 1000A - 2500A |

| SS25, SS25BL | Ø100 | Ø70-Ø100 | ≤ Ø160 | 60-100 | 0.008 | 2500A - 5000A |

SS11, SS11BL, SS12, SS12BL Water Cooling Heatsink Specifications

| Type | Surface diameter | Applicable case surface | Mounting force P | Thermal resistance | Weight of heatsink | Application | ||

| Plate surface | Raised surface | Raised surface | Plate surface | kN | °C/W | kg | ||

| SS11, SS11BL | Ø45 | Ø23, Ø27 | Ø19-Ø40 | Ø24-Ø27 | 3.3-20 | 0.026 | ≥ 0.7 | 200-800A devices, water flow ≥ 4L/Min |

| SS12, SS12BL | Ø55 | Ø32, Ø37, Ø41 | Ø34-Ø40 | Ø32-Ø41 | 5.5-25 | 0.018 | ≥ 1.1 | |

SS11, SS12 Monopipe Water Cooling Heatsink for single device

| Type | Outline size | Arcpower lead size | Mounting size | ||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | d2 | c | e | f | |

| SS11 | 140 | 135 | 145 | 53 | 4 | 30 | 112 | 64 | 105 | 2-Ø9 | 9x14 | M3 | 20 | 35 | 6 |

| SS12 | 190 | 160 | 152 | 78 | 5 | 40 | 140 | 64 | 105 | 2-Ø13 | 11x14 | M3 | 20 | 65 | 8 |

|

|||||||||||||||

SS11BL, SS12BL Doublepipe Water Cooling Heatsink for double devices

| Type | Outline size | Arcpower lead size | Mounting size | ||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | d2 | c | e | f | |

| SS11BL | 140 | 135 | 215 | 53 | 4 | 30 | 112 | 64 | 173 | 3-Ø9 | 9x14 | M3 | 20 | 35 | 6 |

| SS12BL | 190 | 160 | 220 | 78 | 5 | 40 | 140 | 64 | 174 | 3-Ø13 | 11x14 | M3 | 20 | 65 | 8 |

|

|||||||||||||||

SS13, SS13BL, SS14, SS14BL Water Cooling Heatsink Specifications

| Type | Surface diameter | Applicable case surface | Mounting force P | Thermal resistance | Weight of heatsink | Application |

| mm | mm | kN | °C/W | kg | ||

| SS13, SS13BL | Ø68 | Ø40-Ø65 | 15-34 | 0.015 | ≥ 1.7 | 500-2000A devices, water flow ≥ 6L/Min. 1500-2500A devices, water flow ≥ 7L/Min. |

| SS14, SS14BL | Ø84 | Ø50-Ø73 | 18-47 | 0.013 | ≥ 2.2 |

SS13, SS14 Monopipe Water Cooling Heatsink for single device

| Type | Outline size | Arcpower lead size | Mounting size | |||||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | d2 | a | b | c | e | f | g | |

| SS13 | 190 | 160 | 152 | 78 | 6 | 50 | 140 | 64 | 105 | 4-Ø13 | 11x13 | M3 | 15 | 20 | 15 | 65 | 8 | 20 |

| SS14 | 220 | 195 | 188 | 85 | 6 | 55 | 165 | 74 | 130 | 4-Ø13 | 11x13 | M3 | 17.5 | 20 | 20 | 65 | 10 | 20 |

|

||||||||||||||||||

SS13BL, SS14BL Doublepipe Water Cooling Heatsink for double devices

| Type | Outline size | Arcpower lead size | Mounting size | |||||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | d2 | a | b | c | e | f | g | |

| SS13BL | 190 | 160 | 220 | 78 | 6 | 50 | 140 | 64 | 172 | 6-Ø13 | 11x13 | M3 | 15 | 20 | 15 | 65 | 8 | 20 |

| SS14BL | 220 | 195 | 268 | 85 | 6 | 55 | 165 | 74 | 210 | 6-Ø13 | 11x13 | M3 | 17.5 | 20 | 20 | 65 | 10 | 20 |

|

||||||||||||||||||

SS15, SS15BL Water Cooling Heatsink Specifications

| Type | Surface diameter | Applicable case surface | Mounting force P | Thermal resistance | Weight of heatsink | Application |

| mm | mm | kN | °C/W | kg | ||

| SS15, SS15BL | Ø100 | Ø73-Ø100 | 60-70 | 0.011 | ≥ 5.0 | 2000-3000A devices, water flow ≥ 8L/Min |

SS15 Monopipe Water Cooling Heatsink for single device

| Type | Outline size | Arcpower lead size | Mounting size | |||||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | a | b | c | g | ||||

| SS15 | 306 | 260 | 235 | 118 | 7 | 80 | 220 | 90 | 164 | 8-Ø13 | 11x13 | 20 | 40 | 20 | 40 | |||

|

||||||||||||||||||

SS15BL Doublepipe Water Cooling Heatsink for double devices

| Type | Outline size | Arcpower lead size | Mounting size | |||||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | a | b | c | g | ||||

| SS15BL | 306 | 260 | 320 | 118 | 7 | 80 | 220 | 90 | 258 | 12-Ø13 | 11x13 | 20 | 40 | 20 | 40 | |||

|

||||||||||||||||||

SS16, SS16BL Water Cooling Heatsink Specifications

| Type | Surface diameter | Applicable case surface | Mounting force P | Thermal resistance | Weight of heatsink | Application |

| mm | mm | kN | °C/W | kg | ||

| SS16, SS16BL | Ø108 | Ø73-Ø100 | 60-100 | 0.008 | ≥ 8.0 | 3000-6500A devices, water flow ≥ 8L/Min |

SS16 Monopipe Water Cooling Heatsink for single device

| Type | Outline size | Arcpower lead size | Mounting size | |||||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | a | b | c | g | ||||

| SS16 | 356 | 310 | 270 | 125 | 10 | 100 | 260 | 94 | 200 | 8-Ø13 | 11x13 | 25 | 50 | 25 | 50 | |||

|

||||||||||||||||||

SS16BL Doublepipe Water Cooling Heatsink for double device

| Type | Outline size | Arcpower lead size | Mounting size | |||||||||||||||

| L | D | H | L1 | H1 | D1 | D2 | H2 | H3 | d | d1 | a | b | c | g | ||||

| SS16BL | 356 | 310 | 380 | 125 | 10 | 100 | 260 | 94 | 310 | 12-Ø13 | 11x13 | 25 | 50 | 25 | 50 | |||

|

||||||||||||||||||

SS24, SS25 – improved types of SS14, SS15 Series Water Cooling Heatsink

| Type | Surface diameter | Applicable case surface | Mounting force P | Thermal resistance | Application |

| mm | mm | kN | °C/W | ||

| SS24, SS24BL | Ø84 | Ø50-Ø84 | 18-70 | 0.010 | 1000-2500A devices, water flow ≥ 6L/Min |

| SS25, SS25BL | Ø100 | Ø70-Ø100 | 60-100 | 0.008 | 2500-5000A devices, water flow ≥ 8L/Min |

SS24 Monopipe Water Cooling Heatsink for single device

|

SS24BL Doublepipe Water Cooling Heatsink for double devices

|

SS25 Monopipe Water Cooling Heatsink for single device

|

SS25BL Doublepipe Water Cooling Heatsink for double devices

|

High Power Semiconductors AS ENERGITM

Our company is engaged in the manufacturer and sale of wide range of power semiconductors (power thyristors, modules, rectifier diodes, avalanche, rotor and welding diodes, triacs etc.) currents up to 15000A and voltages to 9000V, and air and water heatsinks to them.

You can buy semiconductor devices in any volumes, and when ordering large lots, the price will be lower. We have earned the trust of customers and supply products all over the world.

For questions regarding the acquisition of Power Thyristors, Diodes, Modules send an email request to:

And we will provide you a commercial offer for delivery.

For a large number, we will provide an individual price!!!

We are open to manufacture products at our production facilities

according to your requests and technical task.

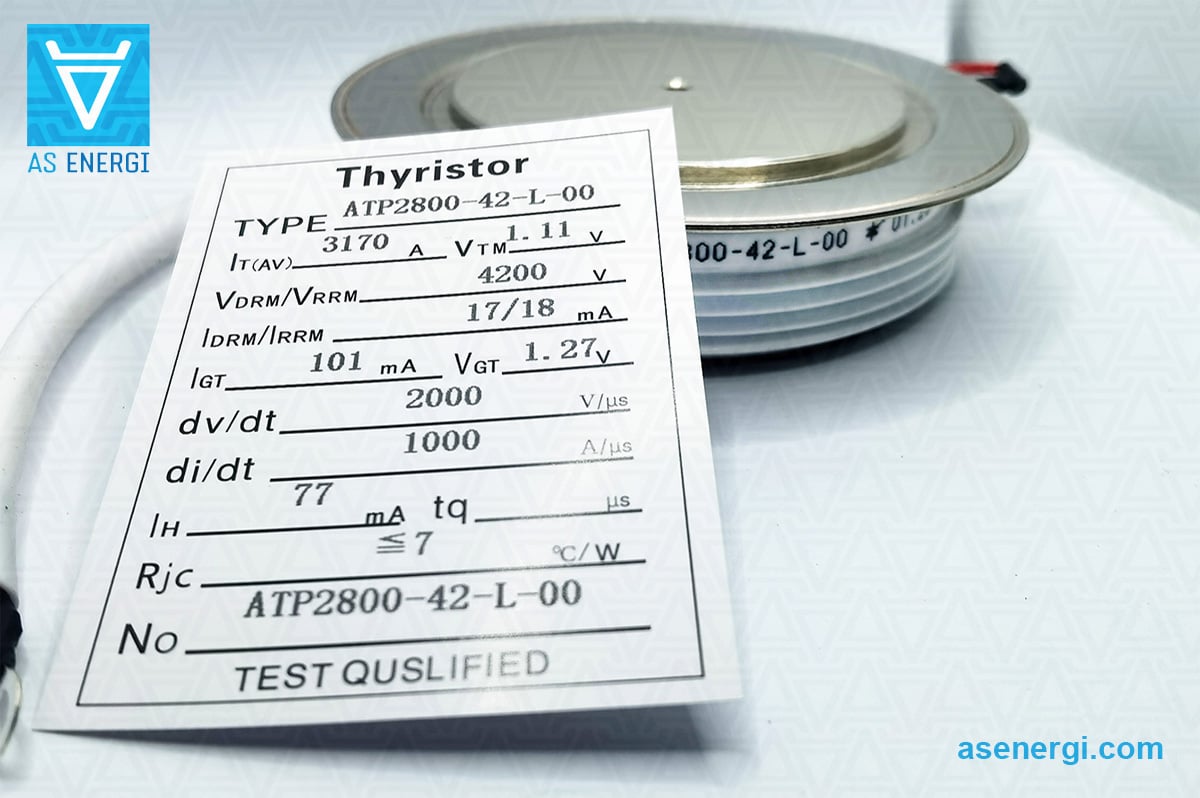

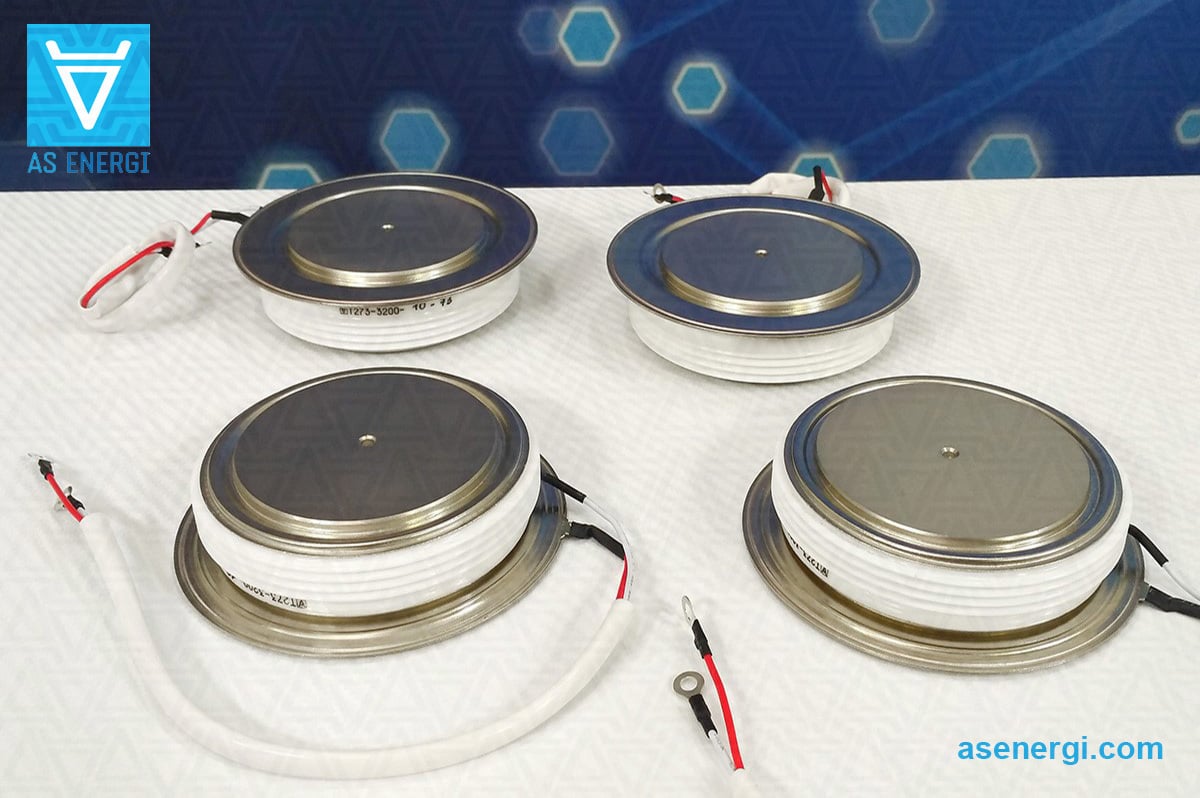

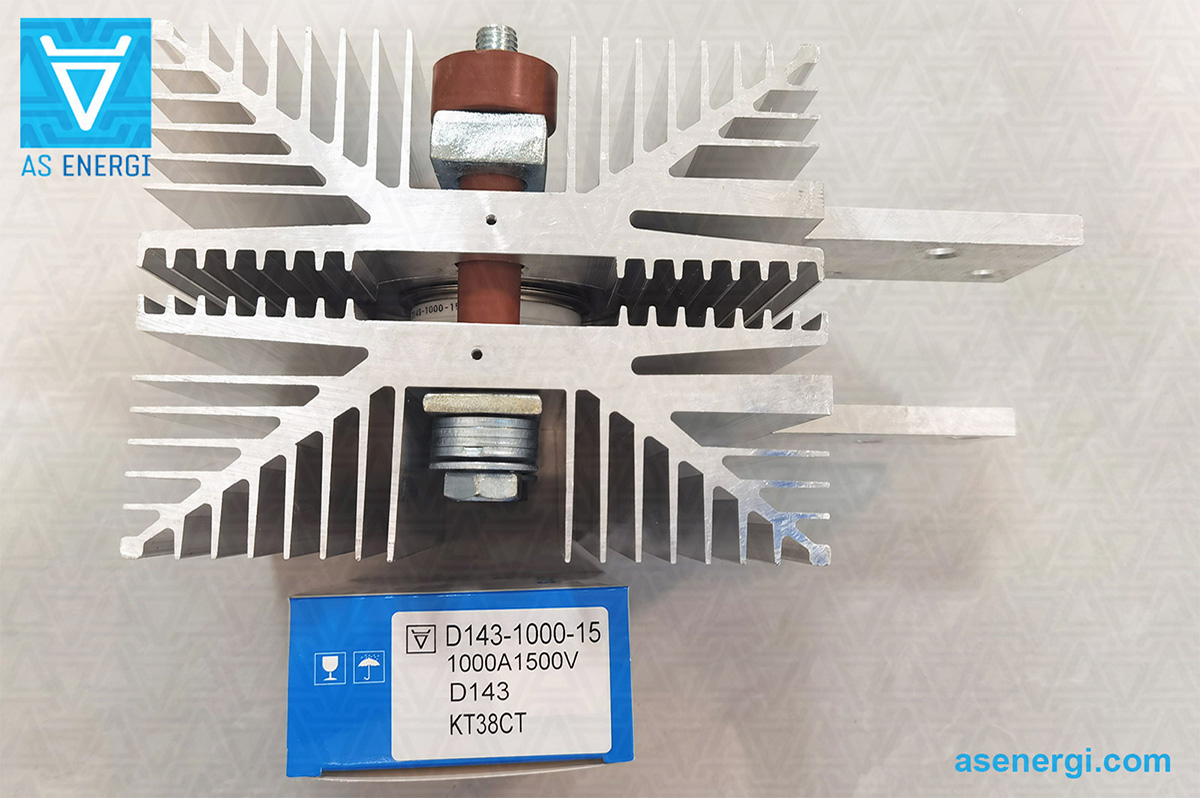

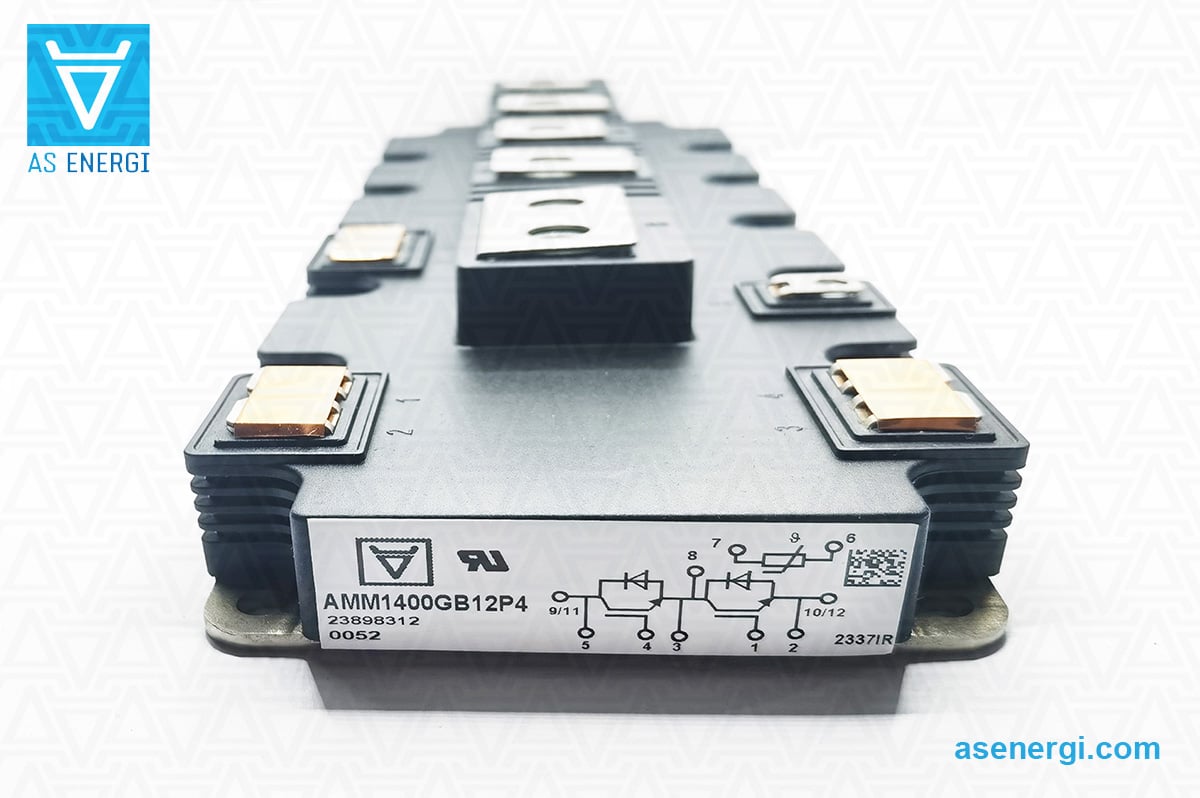

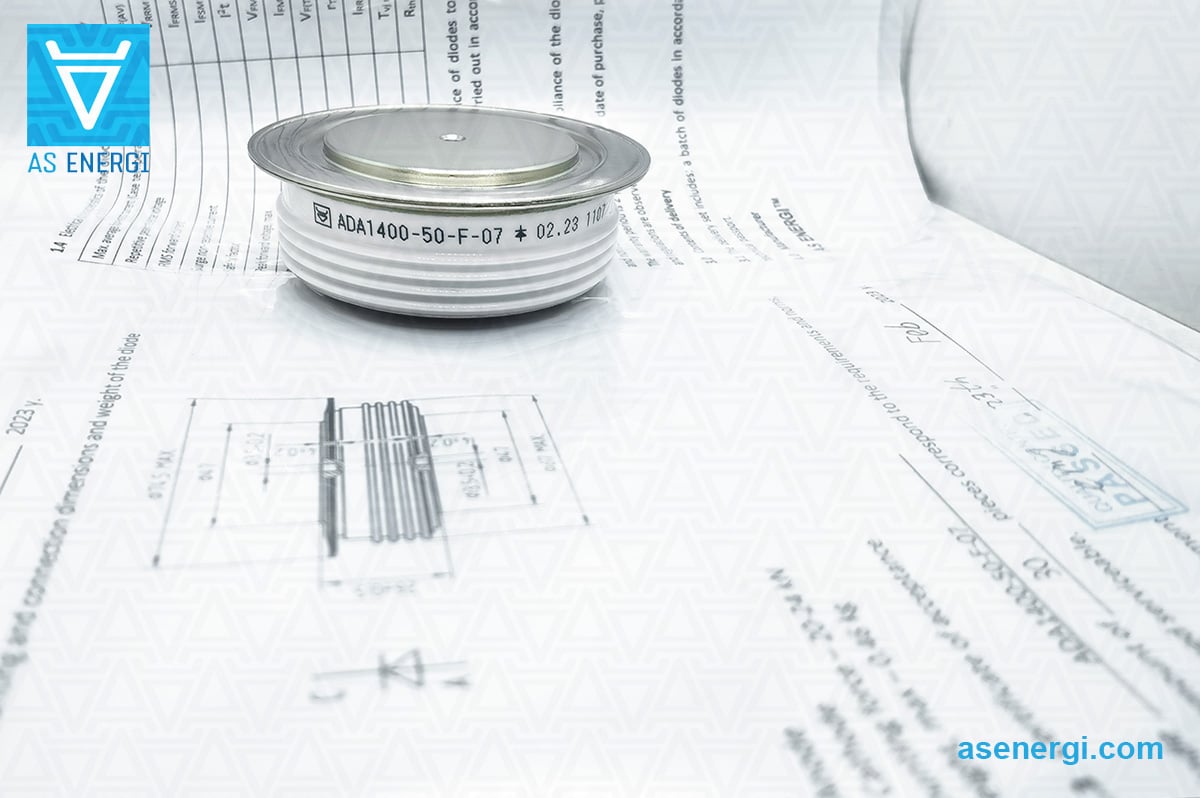

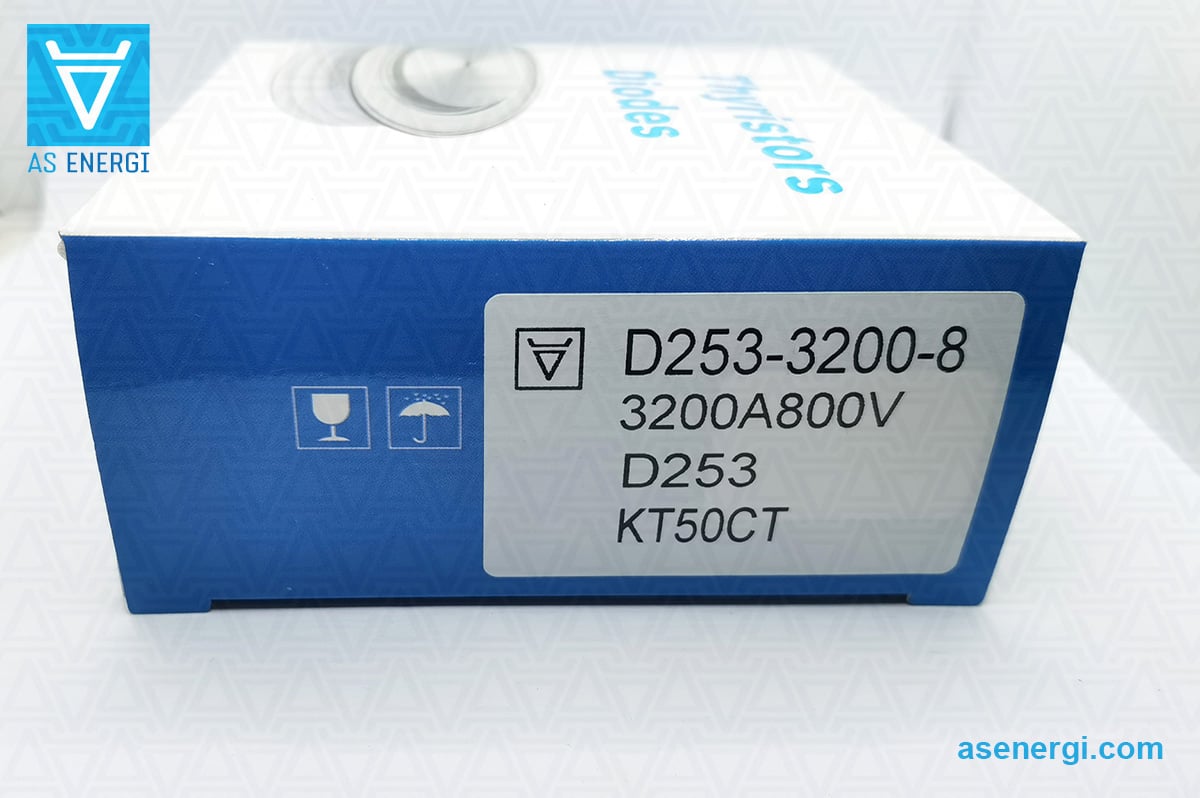

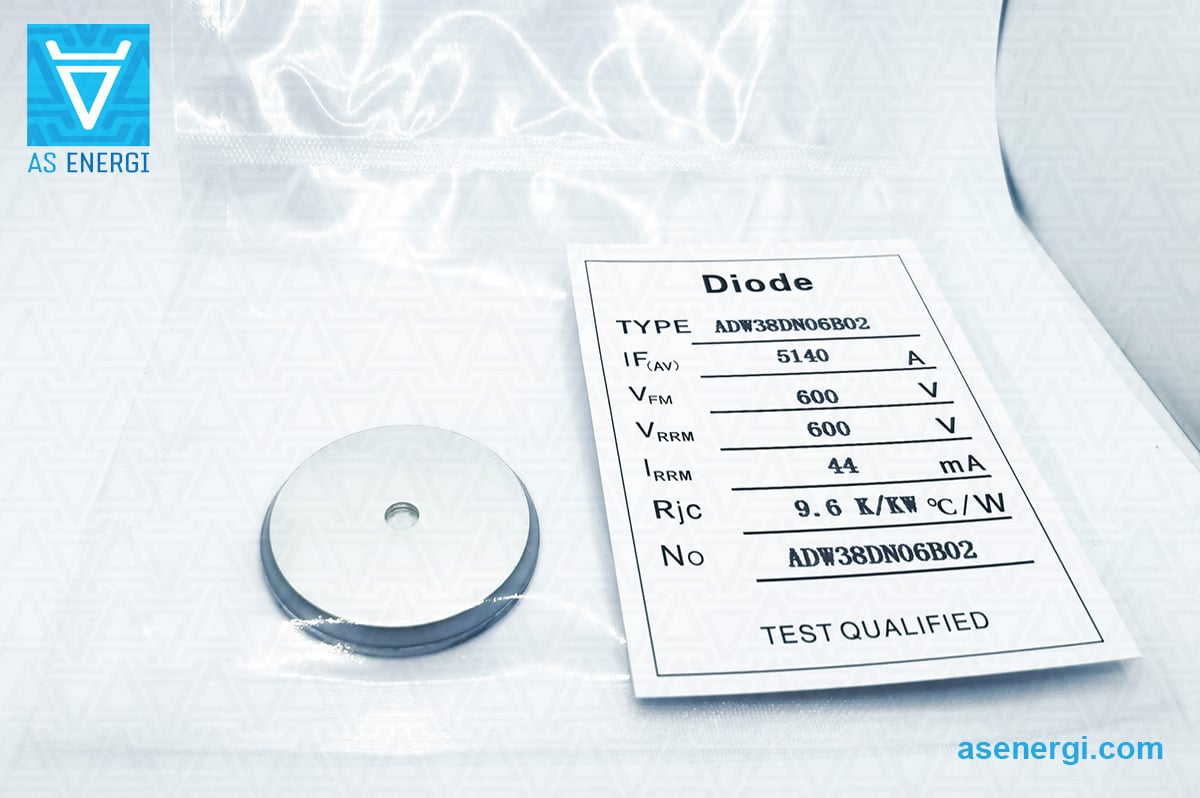

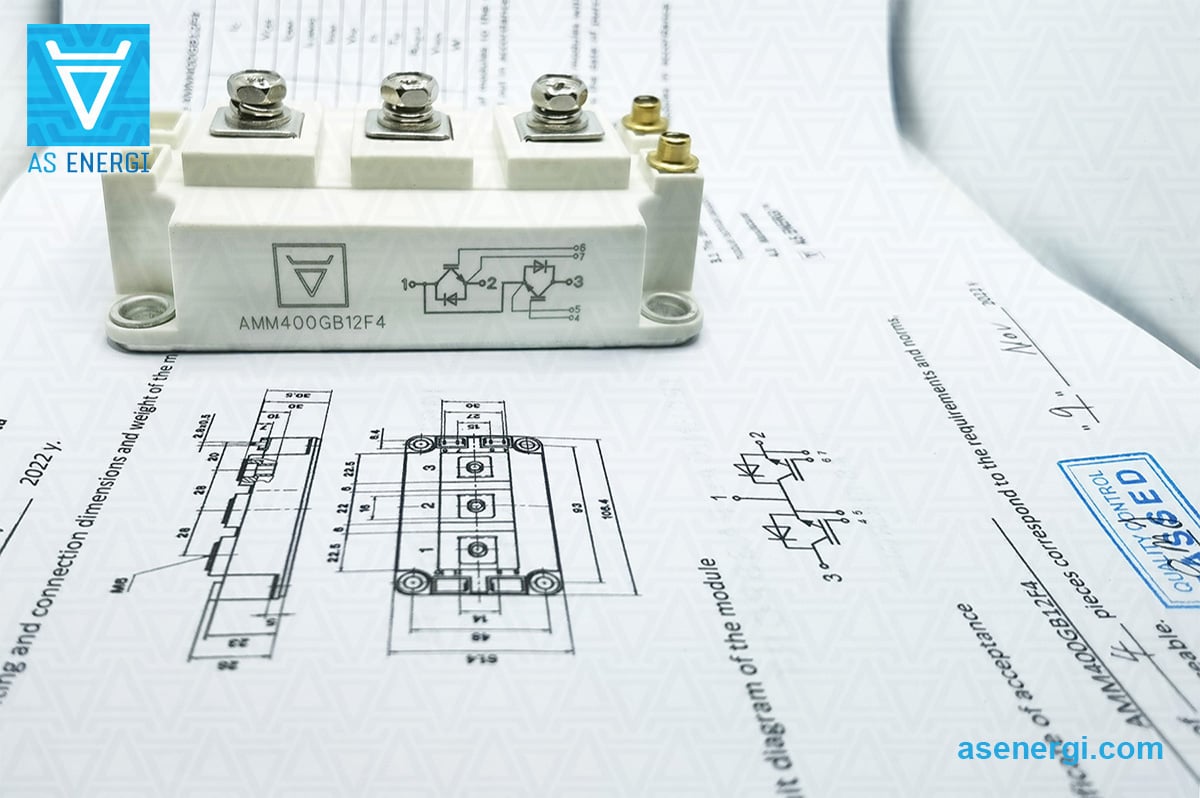

Photo Gallery

The photo gallery shows many different semiconductor devices, semiconductor chips and SCRs produced by AS ENERGITM, examples of test reports.

Why choose AS ENERGITM

Why choose AS ENERGITM

- Own production facilities, including semiconductor silicon chips production

- European brand - 100% quality, favorable price, short production terms

- Over 20 years of experience in the semiconductor industry

- Clients from more than 50 countries trust us

- 20000 items in the product line for currents from 10A to 15000A, voltages from 100V to 9000V

- We produce analogues of other manufacturers' products

- Guaranteed certified quality, warranty period of operation - 2 years

Quality Warranty

Our products are certified and correspond to international standards.

Our company provides a quality guarantee for products of 2 years.

We provide certificates of conformity, reliability reports, data sheets and technical passports at the request of the customer.

Each product is tested for the main parameters, and Test reports of the parameters for each product are provided.

Geography of partnership

AS ENERGITM company manufactures and supplies power semiconductors to more than 50 countries around the world.

Logistics and Delivery

We deliver our products all over the world with the services of logistics companies: DHL, TNT, UPS, EMS, Fedex, Aramex.

Products can be delivered by any means of transport: air, sea, rail and road.

AS ENERGITM Semiconductors Manufacturing

Our products range includes rectifier diodes, phase control thyristors in disc and stud design, avalanche diodes and thyristors, fast switching, high frequency thyristors, fast recovery, welding and rotor diodes, triacs, bridge rectifiers, power modules (thyristor, diode, thyristor-diode, IGBT), and air and water heatsinks to them.

Power diodes and thyristors are produced for currents from 10A to 15000A, voltage range from 100V to 9000V.

Power diode and thyristor modules are produced from 25A and up to 1250A, voltage range 400V - 4400V.

The range of power semiconductors also includes equivalent, replacement, analogue and alternative semiconductor devices of global manufacturers.

Featured Products:

DE

DE IT

IT