Dual Thyristor Modules Kubara Lamina Replacement

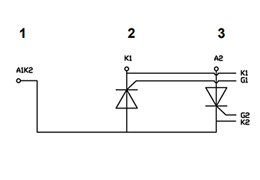

Thyristor Modules are monolithic design with dual topology of semiconductor thyristors (thyristor-thyristor type). Used in DC and AC circuits with loads to 800A and reverse pulse voltages up to 1800V.

Thyristor Modules ASMTC AS ENERGITM is a replacement, equivalent and alternative semiconductor device for SCR Modules MT Series Kubara Lamina.

The thyristor modules are housed in a standard industrial case making it easy to easy integrate of the device into existing equipment.

The modules are designed and assembled in high reliable pressure contact and in solder bond technology which addresses the specific requirements of cost and performance optimized applications.

Thyristor modules are used in various power equipment - power and control units, electrical drives, power regulators, AC regulators, converters, controllers of blast furnaces or chemical processes, welding equipment, and as rectifiers for AC converters.

Our power modules are offered in several dual and single device topologies for almost all phase control or rectifier applications.

Our company provides a quality guarantee for thyristor / diode modules of 2 years from the date of purchase. When supplying thyristor / diode modules, if necessary, we provide technical passport and certificate of conformity.

The final price of thyristor / diode modules depends on the class, quantity, delivery terms, manufacturer, country of origin and form of payment.

For questions regarding the acquisition of Power Modules, Thyristors, Diodes, send an email request to:

And we will provide you a commercial offer for delivery.

For a large number, we will provide an individual price!!!

We are open to manufacture products at our production facilities

according to your requests and technical task.

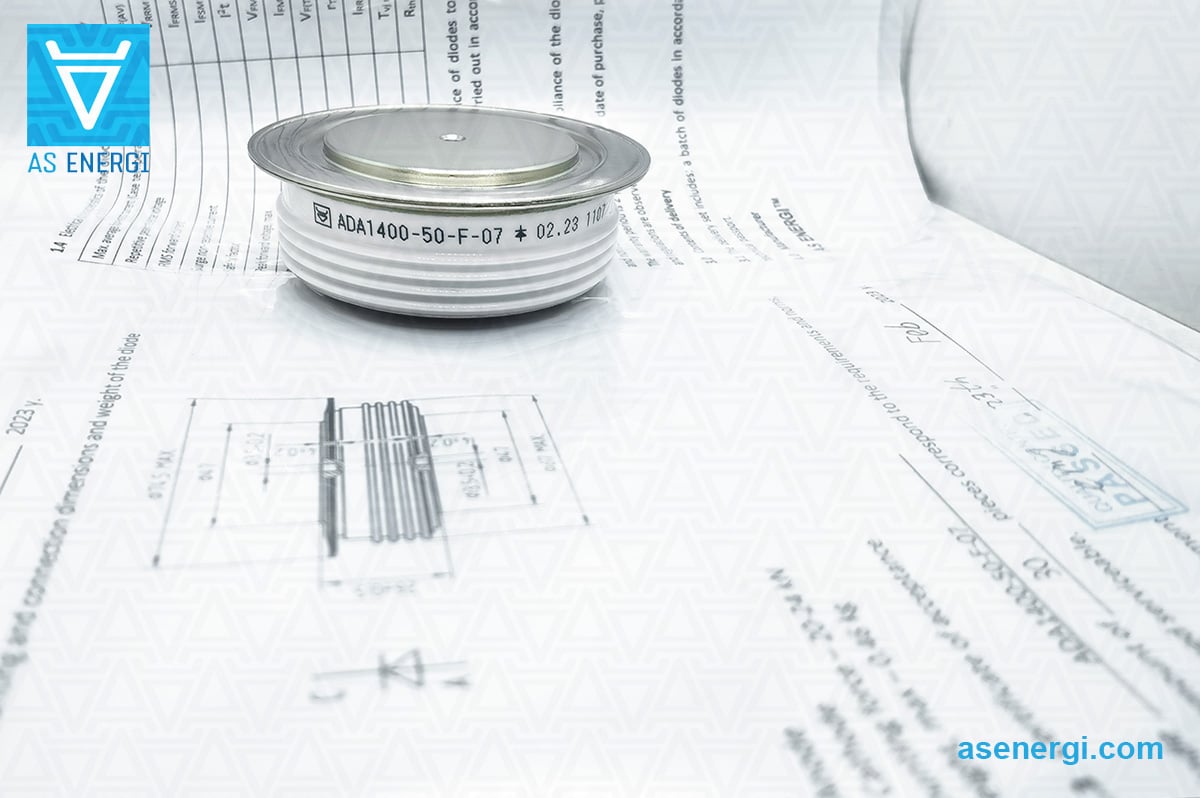

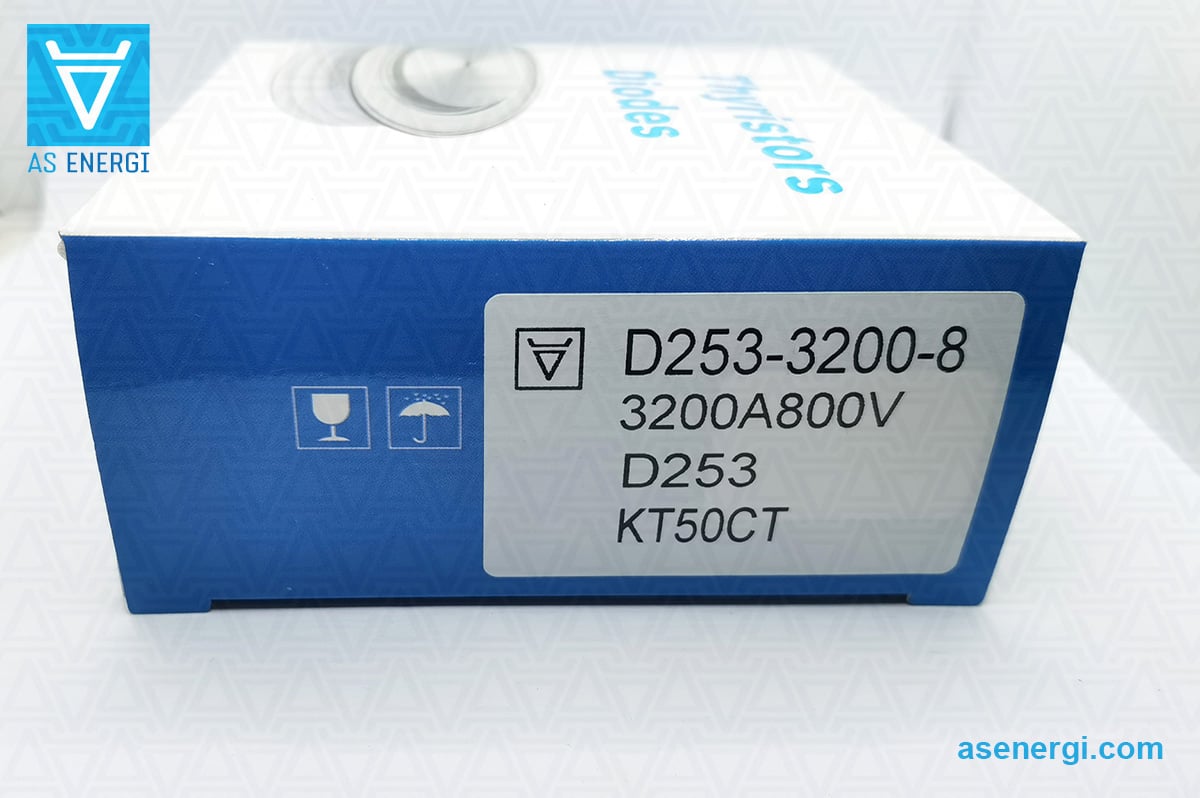

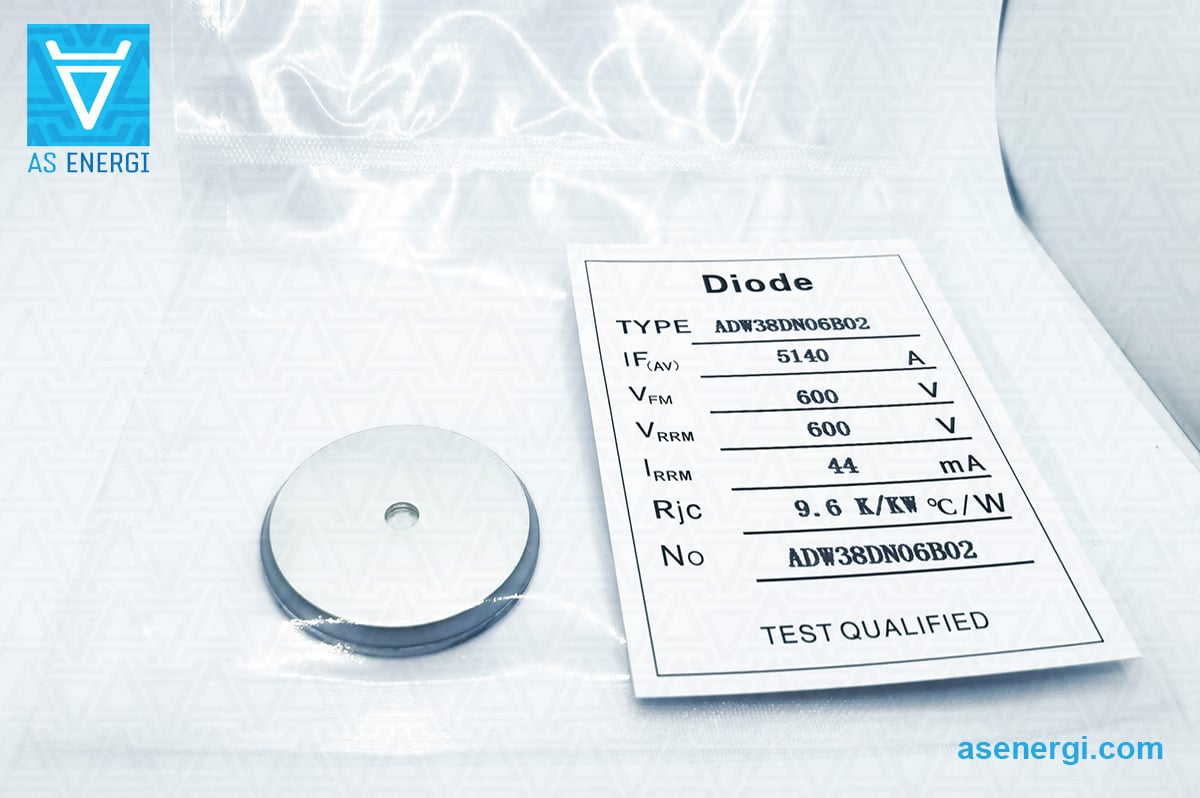

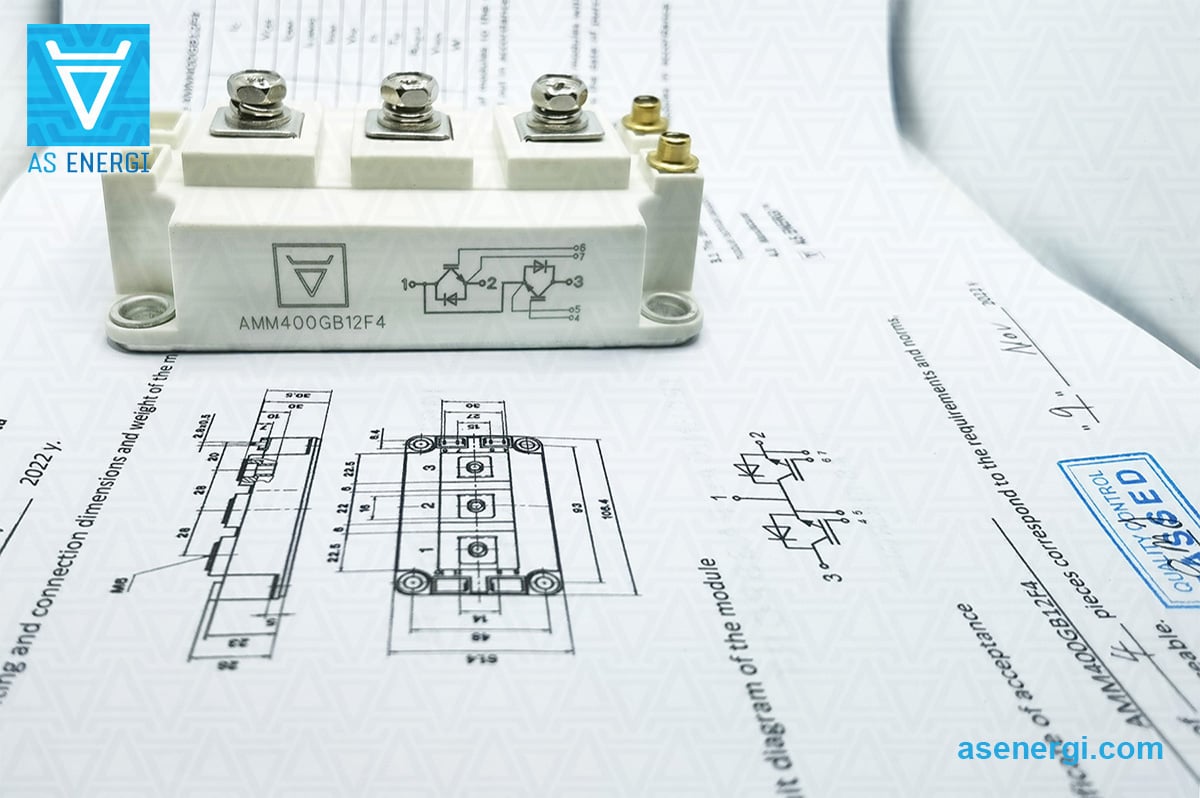

Photo Gallery

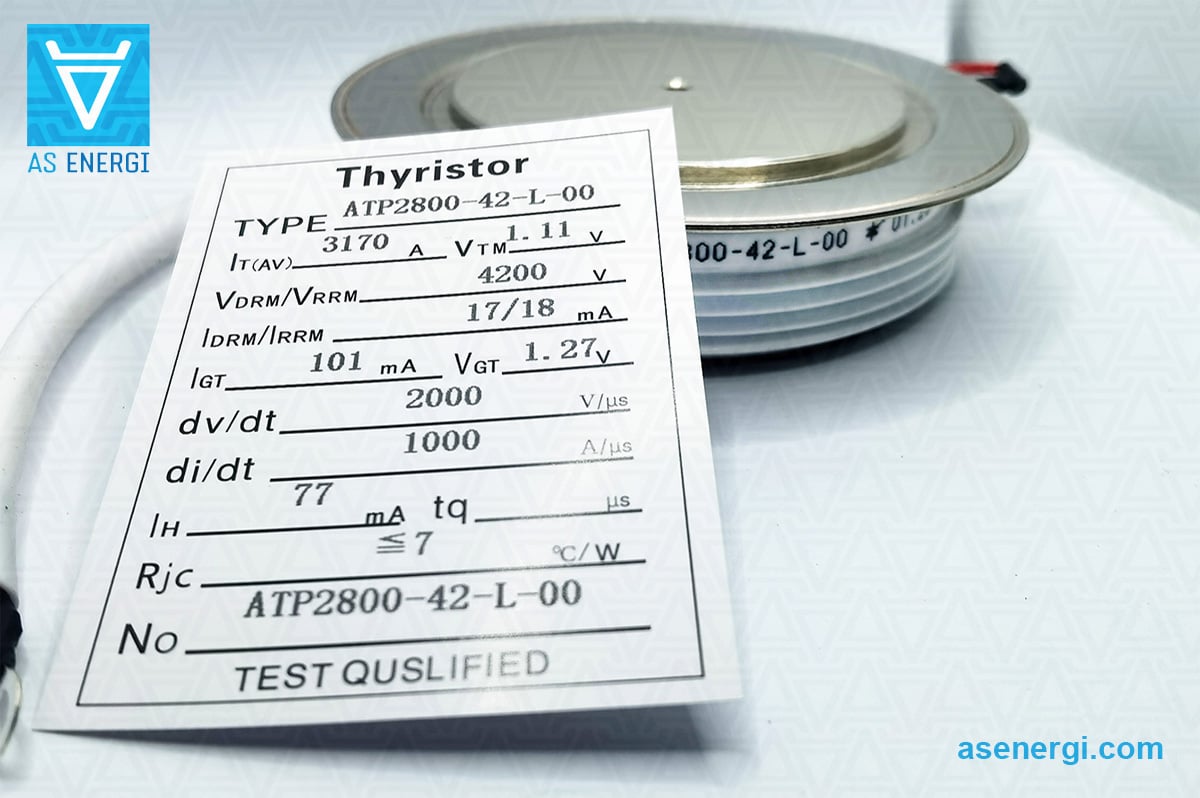

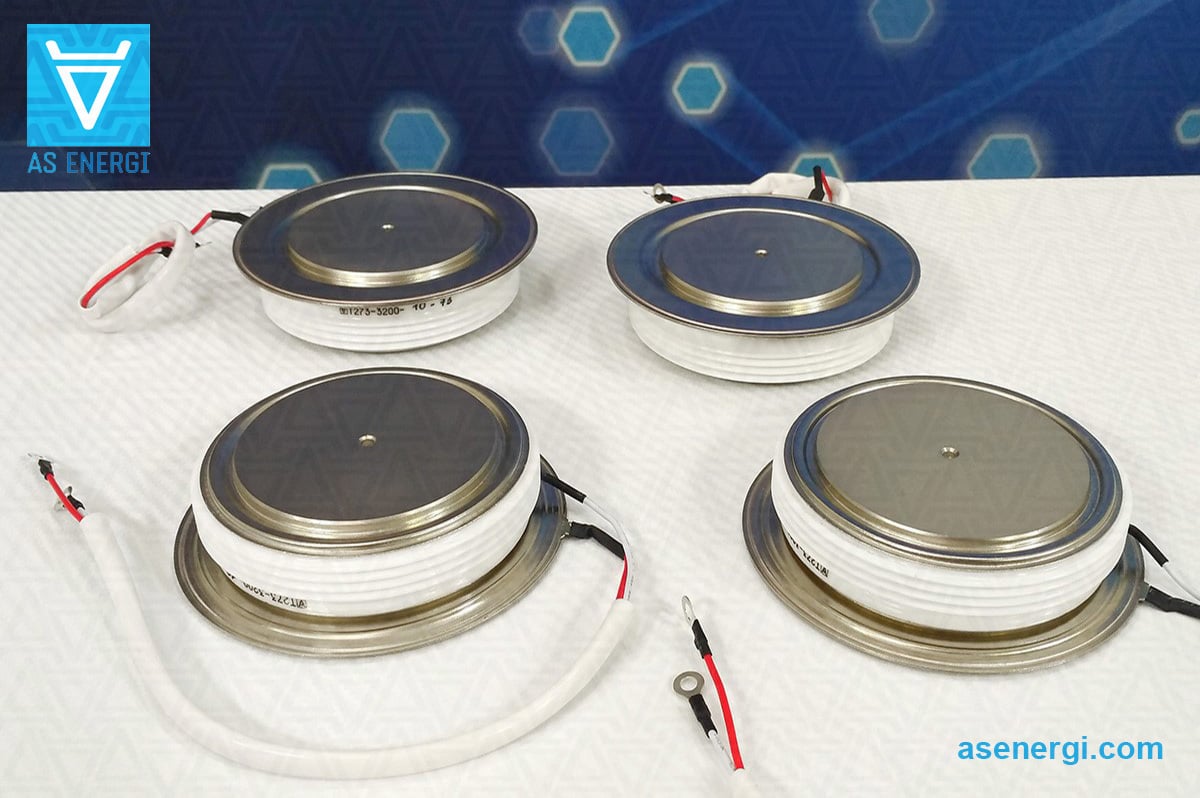

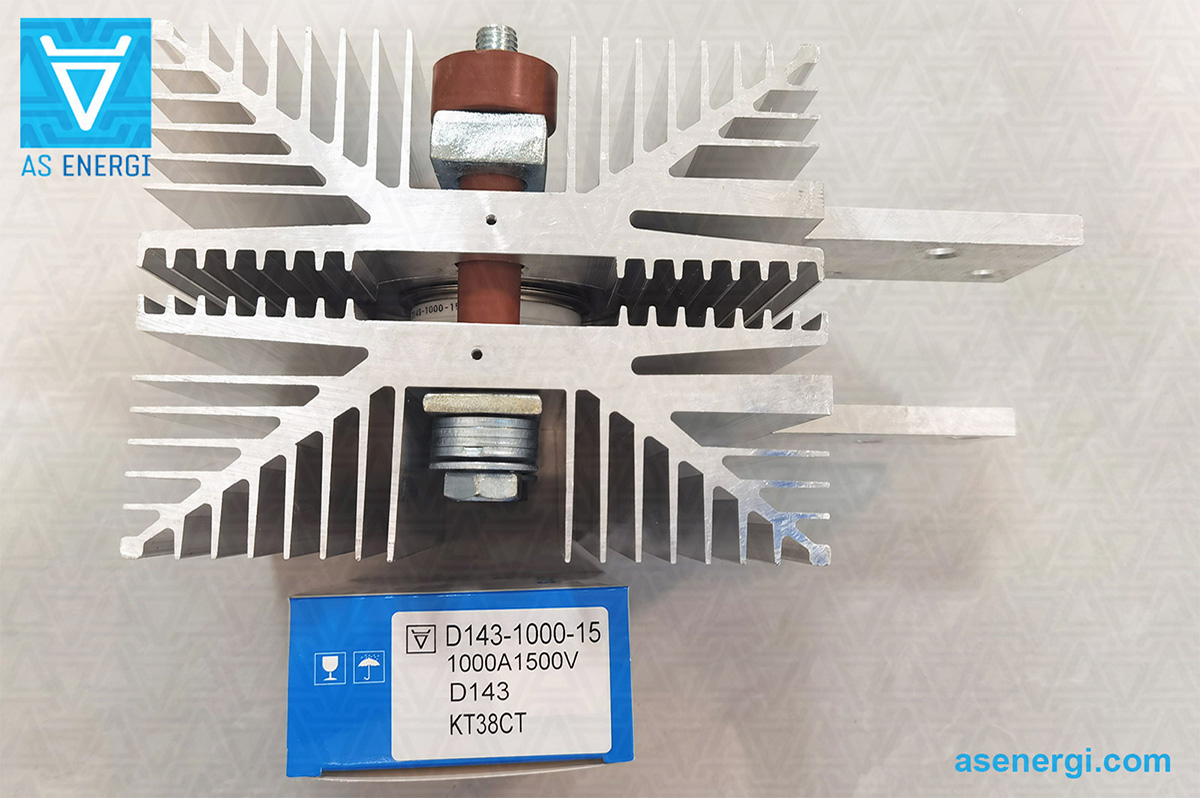

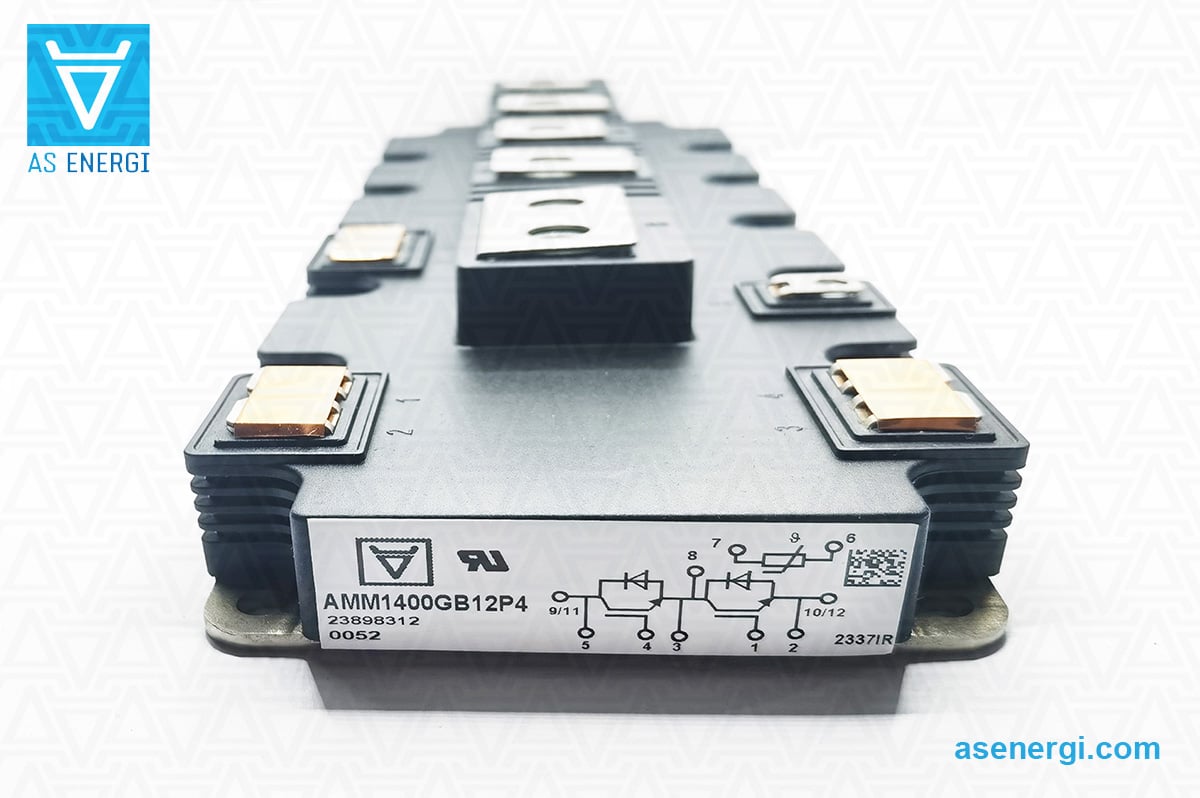

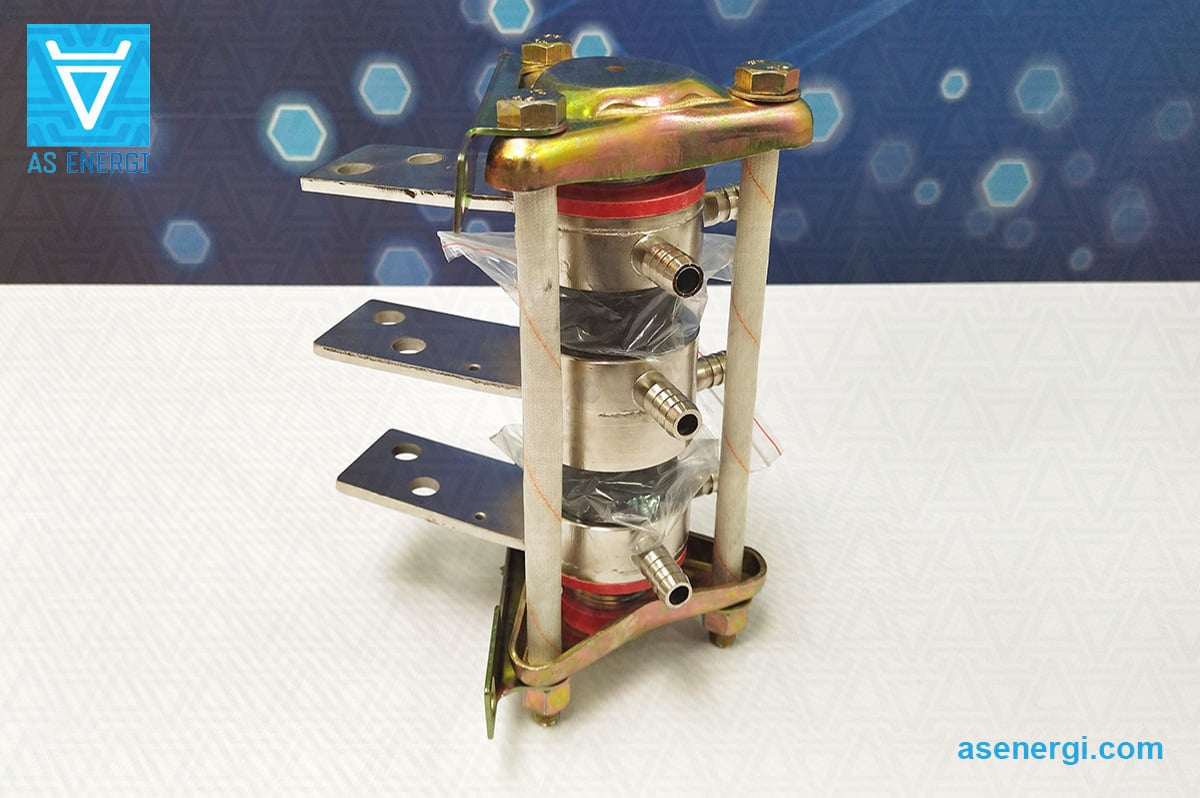

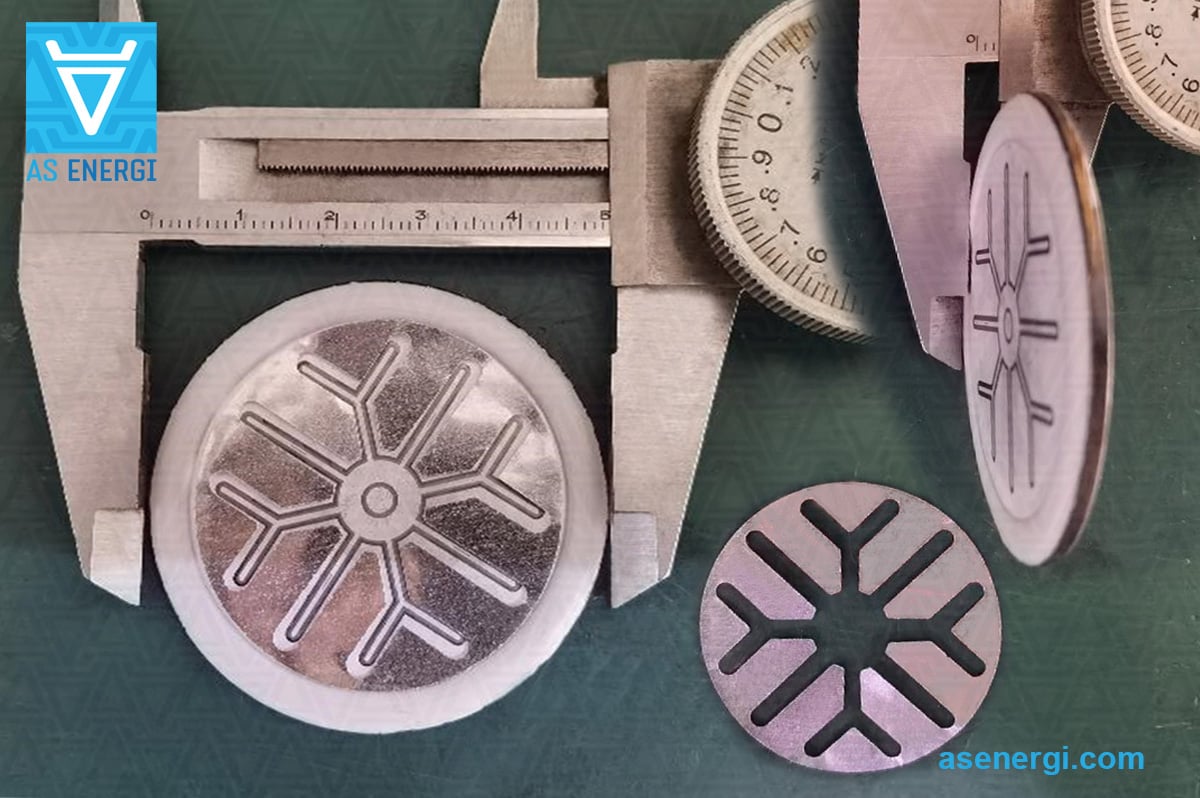

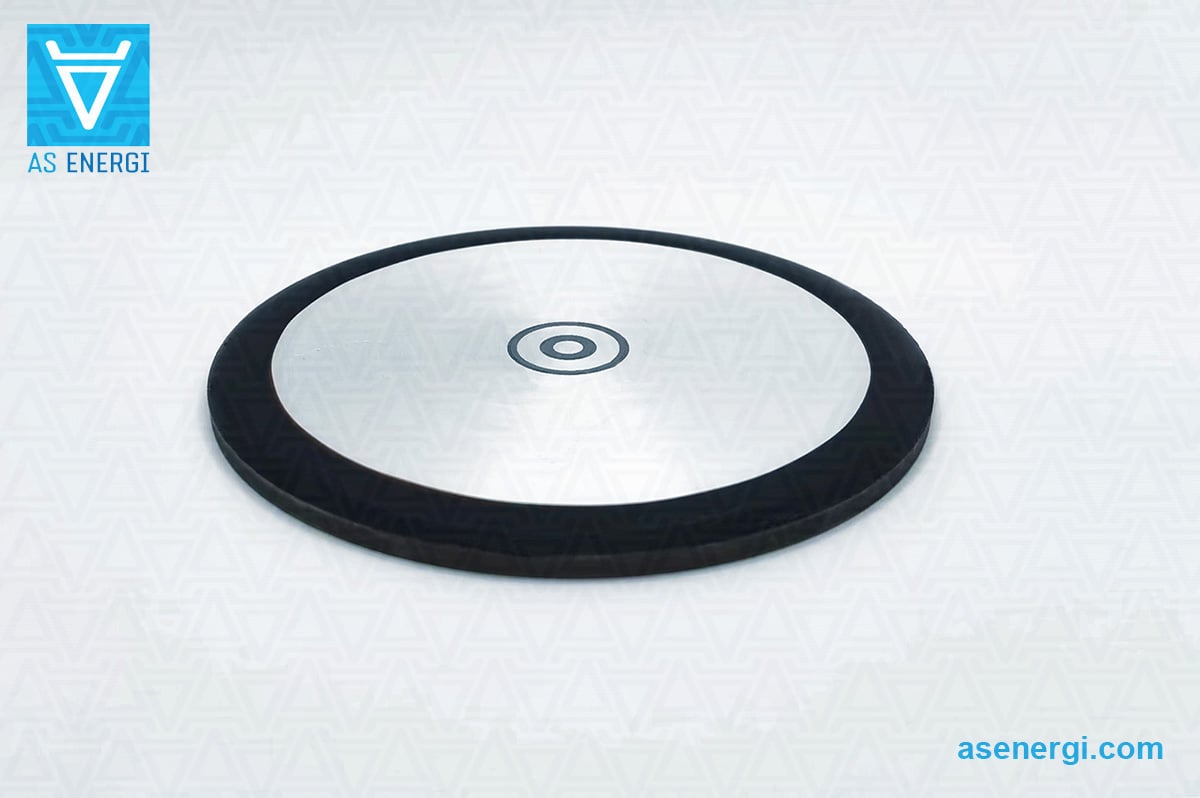

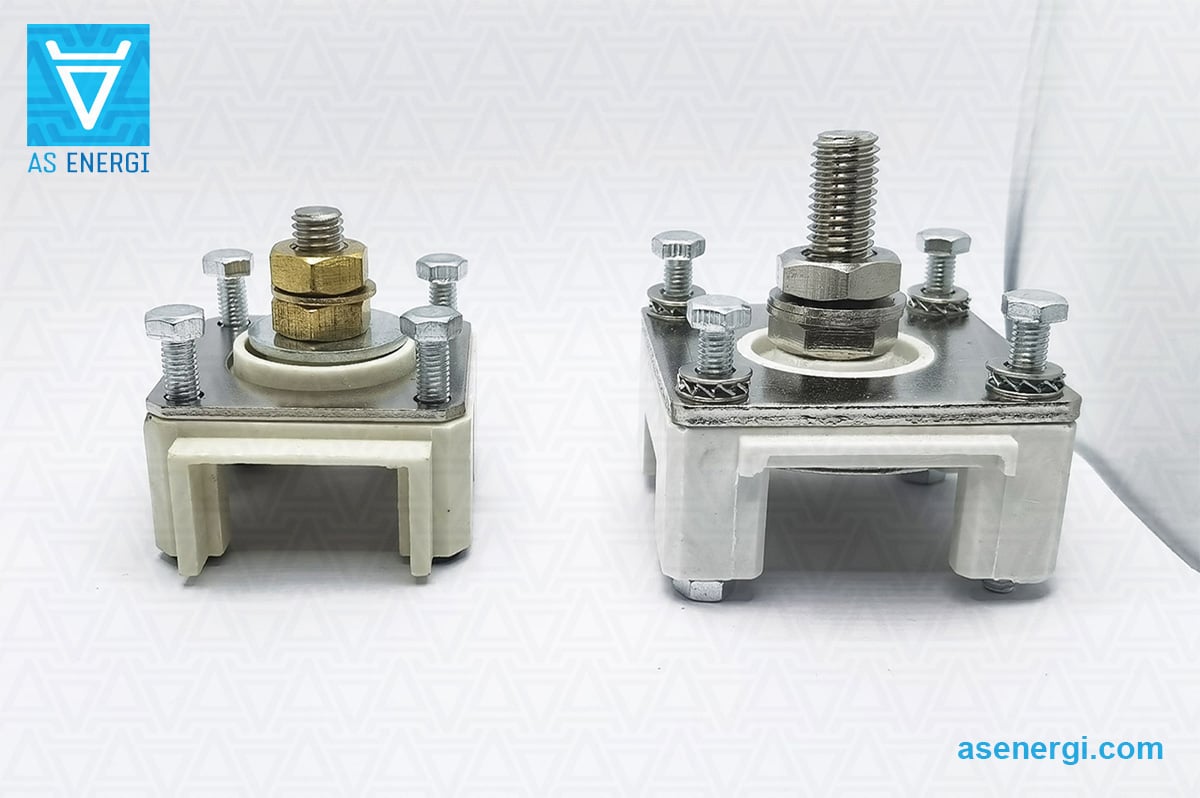

The photo gallery shows many different semiconductor devices, semiconductor chips and SCRs produced by AS ENERGITM, examples of test reports.

General specifications of Thyristor-Thyristor Modules Kubara Lamina and Replacements

| Type | IT(AV)M (TC,°C) |

VRRM | ITSM | I2t | VT0 | rT | Tvj max | Rth(j-c) | W | Dimensions L×B×H | Replacement AS ENERGITM |

Data sheet |

| A | V | A | kA2·s | V | mΩ | ºC | °C/W | g | mm | |||

| MTC-106-04 | 106 (85) | 400 | 2250 | 25 | 0.9 | 2.0 | 125 | 0.28 | 95 | 93x20x30 | ASMTC-106-04 | |

| MTC-106-06 | 106 (85) | 600 | 2250 | 25 | 0.9 | 2.0 | 125 | 0.28 | 95 | 93x20x30 | ASMTC-106-06 | |

| MTC-106-08 | 106 (85) | 800 | 2250 | 25 | 0.9 | 2.0 | 125 | 0.28 | 95 | 93x20x30 | ASMTC-106-08 | |

| MTC-106-10 | 106 (85) | 1000 | 2250 | 25 | 0.9 | 2.0 | 125 | 0.28 | 95 | 93x20x30 | ASMTC-106-10 | |

| MTC-106-12 | 106 (85) | 1200 | 2250 | 25 | 0.9 | 2.0 | 125 | 0.28 | 95 | 93x20x30 | ASMTC-106-12 | |

| MTC-106-14 | 106 (85) | 1400 | 2250 | 25 | 0.9 | 2.0 | 125 | 0.28 | 95 | 93x20x30 | ASMTC-106-14 | |

| MTC-106-16 | 106 (85) | 1600 | 2250 | 25 | 0.9 | 2.0 | 125 | 0.28 | 95 | 93x20x30 | ASMTC-106-16 | |

| MTC-150-04 | 150 (85) | 400 | 4200 | 88 | 0.915 | 1.4 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-150-04 | |

| MTC-150-06 | 150 (85) | 600 | 4200 | 88 | 0.915 | 1.4 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-150-06 | |

| MTC-150-08 | 150 (85) | 800 | 4200 | 88 | 0.915 | 1.4 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-150-08 | |

| MTC-150-10 | 150 (85) | 1000 | 4200 | 88 | 0.915 | 1.4 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-150-10 | |

| MTC-150-12 | 150 (85) | 1200 | 4200 | 88 | 0.915 | 1.4 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-150-12 | |

| MTC-150-14 | 150 (85) | 1400 | 4200 | 88 | 0.915 | 1.4 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-150-14 | |

| MTC-150-16 | 150 (85) | 1600 | 4200 | 88 | 0.915 | 1.4 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-150-16 | |

| MTC-170-04 | 170 (85) | 400 | 5000 | 125 | 0.83 | 1.035 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-170-04 | |

| MTC-170-06 | 170 (85) | 600 | 5000 | 125 | 0.83 | 1.035 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-170-06 | |

| MTC-170-08 | 170 (85) | 800 | 5000 | 125 | 0.83 | 1.035 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-170-08 | |

| MTC-170-10 | 170 (85) | 1000 | 5000 | 125 | 0.83 | 1.035 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-170-10 | |

| MTC-170-12 | 170 (85) | 1200 | 5000 | 125 | 0.83 | 1.035 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-170-12 | |

| MTC-170-14 | 170 (85) | 1400 | 5000 | 125 | 0.83 | 1.035 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-170-14 | |

| MTC-170-16 | 170 (85) | 1600 | 5000 | 125 | 0.83 | 1.035 | 125 | 0.17 | 360 | 94x34x34 | ASMTC-170-16 | |

| MTC-260-04 | 260 (85) | 400 | 7000 | 245 | 0.84 | 0.67 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-260-04 | |

| MTC-260-06 | 260 (85) | 600 | 7000 | 245 | 0.84 | 0.67 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-260-06 | |

| MTC-260-08 | 260 (85) | 800 | 7000 | 245 | 0.84 | 0.67 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-260-08 | |

| MTC-260-10 | 260 (85) | 1000 | 7000 | 245 | 0.84 | 0.67 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-260-10 | |

| MTC-260-12 | 260 (85) | 1200 | 7000 | 245 | 0.84 | 0.67 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-260-12 | |

| MTC-260-14 | 260 (85) | 1400 | 7000 | 245 | 0.84 | 0.67 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-260-14 | |

| MTC-260-16 | 260 (85) | 1600 | 7000 | 245 | 0.84 | 0.67 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-260-16 | |

| MTC-300-04 | 300 (85) | 400 | 8000 | 320 | 0.70 | 0.55 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-300-04 | |

| MTC-300-06 | 300 (85) | 600 | 8000 | 320 | 0.70 | 0.55 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-300-06 | |

| MTC-300-08 | 300 (85) | 800 | 8000 | 320 | 0.70 | 0.55 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-300-08 | |

| MTC-300-10 | 300 (85) | 1000 | 8000 | 320 | 0.70 | 0.55 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-300-10 | |

| MTC-300-12 | 300 (85) | 1200 | 8000 | 320 | 0.70 | 0.55 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-300-12 | |

| MTC-300-14 | 300 (85) | 1400 | 8000 | 320 | 0.70 | 0.55 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-300-14 | |

| MTC-300-16 | 300 (85) | 1600 | 8000 | 320 | 0.70 | 0.55 | 125 | 0.11 | 840 | 115x53x52 | ASMTC-300-16 | |

| MTC-500-04 | 500 (85) | 400 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-04 | |

| MTC-500-06 | 500 (85) | 600 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-06 | |

| MTC-500-08 | 500 (85) | 800 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-08 | |

| MTC-500-10 | 500 (85) | 1000 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-10 | |

| MTC-500-12 | 500 (85) | 1200 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-12 | |

| MTC-500-14 | 500 (85) | 1400 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-14 | |

| MTC-500-16 | 500 (85) | 1600 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-16 | |

| MTC-500-18 | 500 (85) | 1800 | 17000 | 1445 | 0.70 | 0.44 | 125 | 0.06 | 1490 | 150x66.5x62 | ASMTC-500-18 | |

| MTC-800-04 | 800 (85) | 400 | 28000 | 4100 | 0.80 | 0.50 | 125 | 0.06 | 3500 | 180x77x80 | ASMTC-800-04 | |

| MTC-800-06 | 800 (85) | 600 | 28000 | 4100 | 0.80 | 0.50 | 125 | 0.06 | 3500 | 180x77x80 | ASMTC-800-06 | |

| MTC-800-08 | 800 (85) | 800 | 28000 | 4100 | 0.80 | 0.50 | 125 | 0.06 | 3500 | 180x77x80 | ASMTC-800-08 | |

| MTC-800-10 | 800 (85) | 1000 | 28000 | 4100 | 0.80 | 0.50 | 125 | 0.06 | 3500 | 180x77x80 | ASMTC-800-10 | |

| MTC-800-12 | 800 (85) | 1200 | 28000 | 4100 | 0.80 | 0.50 | 125 | 0.06 | 3500 | 180x77x80 | ASMTC-800-12 | |

| MTC-800-14 | 800 (85) | 1400 | 28000 | 4100 | 0.80 | 0.50 | 125 | 0.06 | 3500 | 180x77x80 | ASMTC-800-14 | |

| MTC-800-16 | 800 (85) | 1600 | 28000 | 4100 | 0.80 | 0.50 | 125 | 0.06 | 3500 | 180x77x80 | ASMTC-800-16 |

Part Numbering Guide for Thyristor-Thyristor Modules:

| AS | MT | C | – | 800 | – | 06 |

| AS | – | |

| MT | – | Module type: dual thyristor. |

| C | – | Configuration code. |

| 800 | – | Average on-state current IT(AV), Amp. |

| 06 | – | Voltage class VRRM / 100. |

Recommendations for mounting power modules

Heatsink and Surface Specifications, Preparation

In order to ensure good thermal contact and to obtain the thermal contact resistance values specified in the datasheets, the contact surface of the heat sink must be clean and free from dust particles. It is useful to clean the mounting surface of the heat sink with wipes and an alcohol cleaner, e.g. isopropanol, right before the mounting process. The following mechanical specifications have to be met:

– Unevenness of heat sink mounting area must be ≤ 50μm per 100 mm

– Roughness Rz: < 10 μm

– No steps > 10 μm

Heat sink surface specification |

Applying Thermal Paste

Recommended to use stencil printing in order to apply thermal interface material. Recommended to use thermal paste thickness in the range from 50 μm to 100 μm. Applying thermal paste by means of roller is not recommended for mass production as reproducible of an optimized thermal paste thickness cannot be guaranteed.

Mounting torque on heat sink MS

To secure power modules, the use of steel screws in combination with suitable washers and spring lock washers or combination screws is strongly recommended. The specified in datasheet torque value must be observed.

A pre-tightening torque and retightening to the given torque value is recommended. For the screwing process the speed has to be limited and soft torque limitation is recommended to avoid torque peaks, which may occur with pneumatic screwdrivers.

Example of mounting order |

The screws must be tightened in diagonal order with equal torque in several steps until the specified torque value MS has been reached.

Why choose AS ENERGITM

Why choose AS ENERGITM

- Own production facilities, including semiconductor silicon chips production

- European brand - 100% quality, favorable price, short production terms

- Over 20 years of experience in the semiconductor industry

- Clients from more than 50 countries trust us

- 20000 items in the product line for currents from 10A to 15000A, voltages from 100V to 9000V

- We produce analogues of other manufacturers' products

- Guaranteed certified quality, warranty period of operation - 2 years

Quality Warranty

Our products are certified and correspond to international standards.

Our company provides a quality guarantee for products of 2 years.

We provide certificates of conformity, reliability reports, data sheets and technical passports at the request of the customer.

Each product is tested for the main parameters, and Test reports of the parameters for each product are provided.

Geography of partnership

AS ENERGITM company manufactures and supplies power semiconductors to more than 50 countries around the world.

Logistics and Delivery

We deliver our products all over the world with the services of logistics companies: DHL, TNT, UPS, EMS, Fedex, Aramex.

Products can be delivered by any means of transport: air, sea, rail and road.

AS ENERGITM Semiconductors Manufacturing

Our products range includes rectifier diodes, phase control thyristors in disc and stud design, avalanche diodes and thyristors, fast switching, high frequency thyristors, fast recovery, welding and rotor diodes, triacs, bridge rectifiers, power modules (thyristor, diode, thyristor-diode, IGBT), and air and water heatsinks to them.

Power diodes and thyristors are produced for currents from 10A to 15000A, voltage range from 100V to 9000V.

Power diode and thyristor modules are produced from 25A and up to 1250A, voltage range 400V - 4400V.

The range of power semiconductors also includes equivalent, replacement, analogue and alternative semiconductor devices of global manufacturers.

Featured Products:

DE

DE IT

IT