Phase Control Thyristors OLD Part Number Infineon Replacement

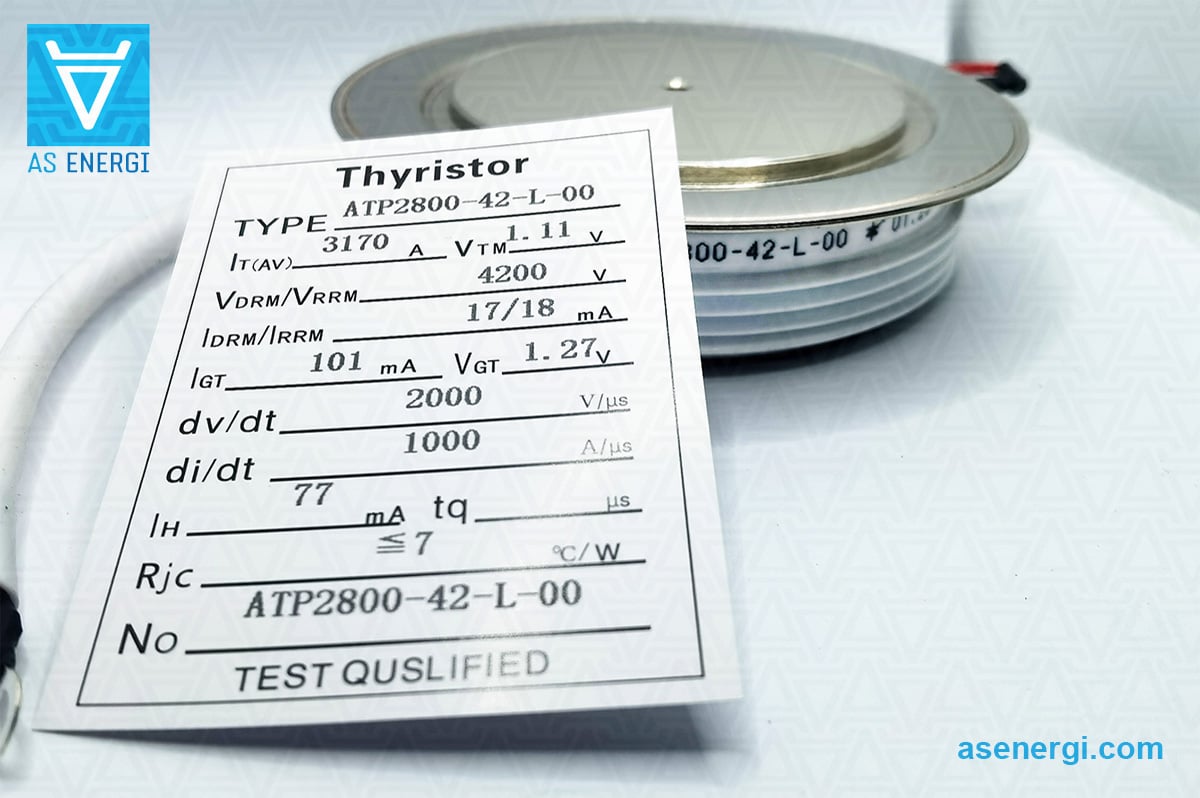

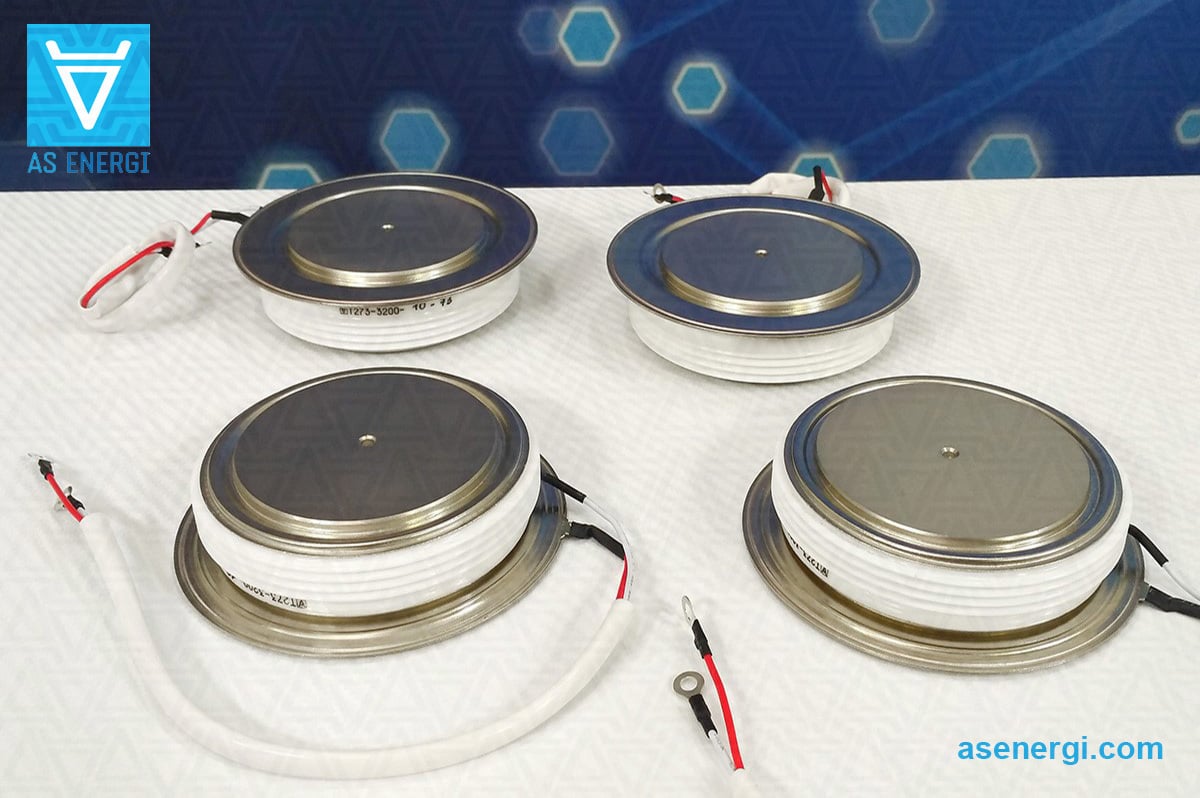

Power phase control thyristors, also known as Thyristor SCR (Silicon Controlled Rectifier), in disc design are press pack type general-purpose thyristors, regulating and converting DC and AC currents up to 3400A in circuits with voltages to 5200V (depends on the thyristor type).

Thyristors ATD AS ENERGITM are a replacement, analog, alternative for presspacks electrical triggered thyristors Infineon Technologies.

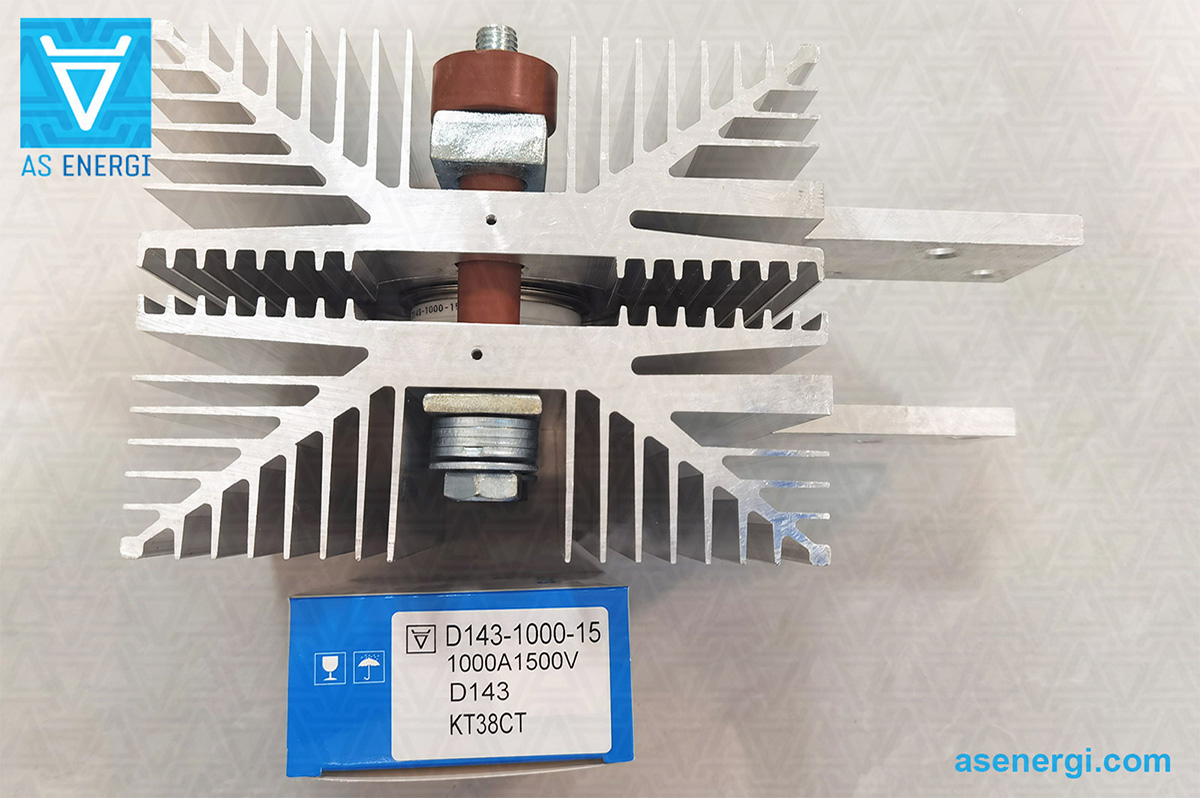

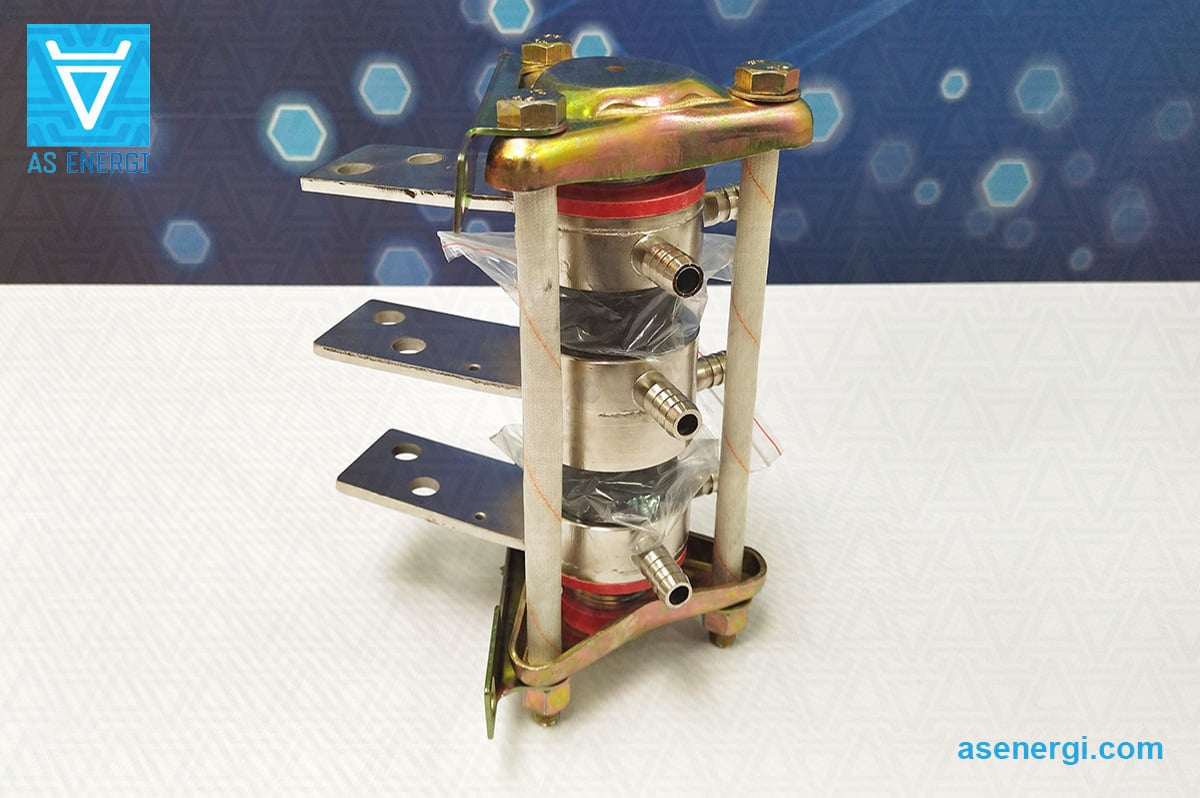

"Air-cooled heatsinks O series for disc devices", "Air heatsink SF series", "Water heatsink SS series" for thyristor cooling are also available to order.

Part numbering guide for phase control thyristors

OLD Part Number is a product line of thyristors that have been discontinued and are no longer produced, AS ENERGITM offers analogues for OLD Part Number Thyristors Infineon.

Features: designed for high power industrial and power transmission applications; optimized for low on-state voltage drop; matched Qrr and VT values available for series and / or parallel connections.

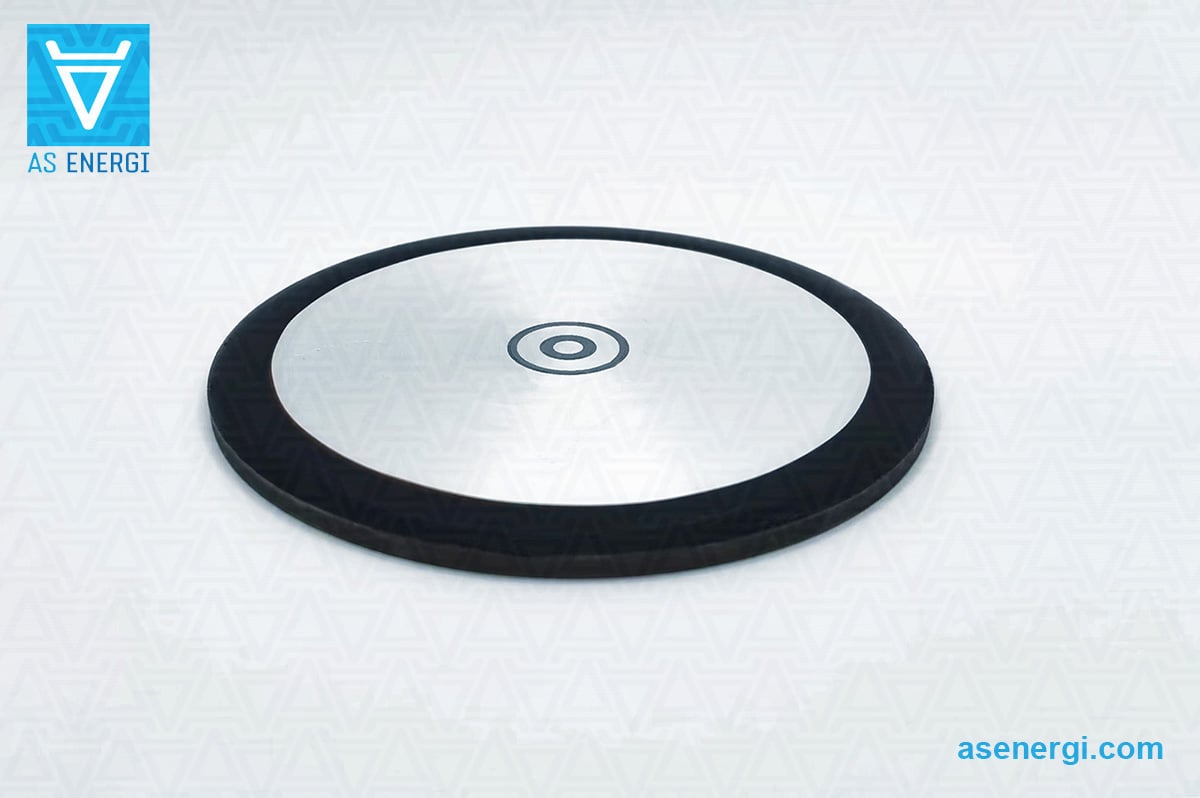

The thyristor has an industry standard ceramic housing making it easy to integrate the device into existing equipment. This thyristor has a disc housing with pressure contacts. The polarity of the thyristor is determined by the icon on the case. The technical specifications, part numbering guide, datashets for thyristors are listed below.

Thyristors AS ENERGITM have the following features: low static and dynamic losses, high values of VDRM/VRRM, extensive experience of using the devices in various industries, range of voltages from 100 to 9000 V and amperages from 100 to 15000 A, high resistance to thermal and electric cycling, natural or forced air cooling.

Our company provides a quality guarantee for thyristors of 2 years from the date of purchase. When supplying thyristors, if necessary, we provide technical passport and certificate of conformity.

The final price of phase control thyristors depends on the voltage class, quantity, delivery terms, manufacturer, country of origin and form of payment.

General specifications of OLD Part Number Phase Control Thyristors Infineon and Replacements

| Type | IT(AV) | VDRM

VRRM |

ITSM | I2t | VT0 | rT | Tvj max | Rth(j-c) | Dimensions | Replacement AS ENERGITM |

Data sheet |

| A | V | kA | kA2·s | V | mΩ | ºC | ºC/W | mm | |||

| Thyristors Stud Type | |||||||||||

| T86N | 86 | 600-1800 | 2 | 20 | 1.00 | 2.60 | 125 | 0.3000 | 210SW27M12 | ATD86N |

|

| T130N | 130 | 600-1800 | 3 | 45 | 1.08 | 1.53 | 125 | 0.2000 | 210SW27M12 | ATD130N |

|

| T160N | 160 | 600-1800 | 3.4 | 58 | 1.08 | 1.53 | 125 | 0.1500 | 210SW27M12 | ATD160N |

|

| T210N | 210 | 200-600 | 5.5 | 151 | 0.80 | 0.85 | 140 | 0.1500 | 210SW27M12 | ATD210N |

|

| T221N | 221 | 600-1800 | 5.7 | 163 | 1.10 | 0.75 | 125 | 0.1200 | 270SW41M24 | ATD221N |

|

| T271N | 270 | 2000-2500 | 7 | 245 | 1.07 | 0.87 | 125 | 0.0910 | 270SW41M24 | ATD271N |

|

| T345N | 345 | 600-1800 | 6.9 | 238 | 0.85 | 0.75 | 125 | 0.0800 | 210SW41M24 | ATD345N |

|

| T370N | 370 | 600-1800 | 8 | 320 | 0.80 | 0.50 | 125 | 0.0850 | 270SW41M24 | ATD370N |

|

| Thyristors Disc Type | |||||||||||

| T178N | 178 | 600-1800 | 2.8 | 34 | 0.92 | 1.50 | 125 | 0.1400 | 41x23x14 | ATD178N |

|

| T218N | 218 | 600-1800 | 3.4 | 58 | 0.90 | 1.35 | 125 | 0.1100 | 41x23x14 | ATD218N |

|

| T298N | 298 | 600-1600 | 4.25 | 90.6 | 0.85 | 0.90 | 125 | 0.0880 | 41x23x14 | ATD298N |

|

| T308N | 308 | 2000-2600 | 4.5 | 100 | 1.10 | 1.60 | 125 | 0.0560 | 50x30x14 | ATD308N |

|

| T348N | 348 | 200-600 | 4 | 80 | 1.00 | 0.70 | 140 | 0.1000 | 41x23x14 | ATD348N |

|

| T358N | 358 | 600-1800 | 4.6 | 106 | 0.85 | 0.90 | 125 | 0.0680 | 41x23x14 | ATD358N |

|

| T378N | 378 | 1200-1600 | 6.3 | 202 | 0.80 | 0.75 | 125 | 0.068 | 41x23x14 | ATD378N |

|

| TЗ80N | 380 | 3200-3800 | 6.5 | 211 | 1.20 | 1.20 | 125 | 0.0450 | 56x34x28 | ATDЗ80N |

|

| T388N | 388 | 600-1800 | 6.4 | 205 | 0.90 | 0.75 | 125 | 0.0680 | 50x30x14 | ATD388N |

|

| T398N | 398 | 200-600 | 5.5 | 151 | 1.00 | 0.40 | 140 | 0.1000 | 41x23x14 | ATD398N |

|

| T399N | 399 | 2000-2600 | 7.9 | 312 | 1.15 | 1.12 | 125 | 0.0410 | 57x36x26 | ATD399N |

|

| T458N | 459 | 2000-2600 | 9 | 405 | 1.00 | 0.84 | 125 | 0.0455 | 60x36x14 | ATD458N |

|

| T459N | 459 | 2000-2600 | 9 | 405 | 1.00 | 0.84 | 125 | 0.0455 | 57x36x26 | ATD459N |

|

| T508N | 510 | 600-1800 | 6.9 | 238 | 0.80 | 0.60 | 125 | 0.0530 | 50x30x14 | ATD508N |

|

| T509N | 510 | 600-1800 | 6.9 | 238 | 0.80 | 0.60 | 125 | 0.0530 | 57x36x26 | ATD509N |

|

| T588N | 588 | 600-1800 | 8 | 320 | 0.80 | 0.50 | 125 | 0.0450 | 50x30x14 | ATD588N |

|

| T589N | 588 | 600-1800 | 8 | 320 | 0.80 | 0.50 | 125 | 0.0450 | 57x36x26 | ATD589N |

|

| T618N | 618 | 600-1400 | 9.5 | 451 | 0.80 | 0.42 | 125 | 0.0450 | 50x30x14 | ATD618N |

|

| T619N | 618 | 600-1400 | 9.5 | 451 | 0.80 | 0.42 | 125 | 0.0450 | 57x36x26 | ATD619N |

|

| T648N | 649 | 800-1600 | 11 | 605 | 1.00 | 0.38 | 125 | 0.039 | 50x30x14 | ATD648N |

|

| T649N | 649 | 800-1600 | 11 | 605 | 1.00 | 0.38 | 125 | 0.039 | 57x36x26 | ATD649N |

|

| T709N | 700 | 2000-2600 | 13 | 845 | 1.05 | 0.53 | 125 | 0.0290 | 75x48x26 | ATD709N |

|

| T718N | 718 | 600-1600 | 12.5 | 781 | 0.85 | 0.35 | 125 | 0.0380 | 60x36x14 | ATD718N |

|

| T719N | 718 | 600-1600 | 12.5 | 781 | 0.85 | 0.35 | 125 | 0.0380 | 57x36x26 | ATD719N |

|

| T729N | 730 | 3600-4200 | 15.8 | 1250 | 1.20 | 0.57 | 125 | 0.0215 | 75x48x26 | ATD729N |

|

| T730N | 730 | 3600-4200 | 15.8 | 1250 | 1.20 | 0.57 | 125 | 0.0215 | 74x50x26 | ATD7З0N |

|

| T828N | 828 | 200-600 | 12 | 720 | 1.00 | 0.23 | 140 | 0.0450 | 50x30x14 | ATD828N |

|

| T860N | 860 | 3000-3600 | 17 | 1445 | 1.08 | 0.50 | 125 | 0.0210 | 74x50x26 | ATD860N |

|

| T869N | 860 | 3000-3600 | 17 | 1445 | 1.08 | 0.50 | 125 | 0.0210 | 75x48x26 | ATD869N |

|

| T879N | 879 | 600-1800 | 15.5 | 1200 | 0.85 | 0.27 | 125 | 0.0300 | 57x36x26 | ATD879N |

|

| T919N | 919 | 2000-2600 | 17 | 1445 | 1.20 | 0.40 | 125 | 0.0210 | 75x48x26 | ATD919N |

|

| T1059N | 1050 | 2000-2800 | 19 | 1800 | 1.05 | 0.30 | 125 | 0.0210 | 75x48x26 | ATD1059N |

|

| T1050N | 1050 | 2000-2800 | 19 | 1800 | 1.05 | 0.30 | 125 | 0.0210 | 74x50x26 | ATD1050N |

|

| T1078N | 1078 | 200-600 | 14.5 | 1050 | 1.02 | 0.2 | 140 | 0.0330 | 50x30x14 | ATD1078N |

|

| T1099N | 1100 | 600-1600 | 20 | 2000 | 0.84 | 0.195 | 125 | 0.0260 | 75x48x26 | ATD1099N |

|

| T1189N | 1190 | 1200-1800 | 22.5 | 2530 | 0.90 | 0.19 | 125 | 0.0230 | 75x48x26 | ATD1189N |

|

| T1200N | 1200 | 1200-1800 | 24 | 2880 | 1.05 | 0.185 | 125 | 0.0210 | 74x50x26 | ATD1200N |

|

| T1209N | 1200 | 1200-1800 | 24 | 2880 | 1.05 | 0.185 | 125 | 0.0210 | 75x48x26 | ATD1209N |

|

| T1258N | 1258 | 200-600 | 20 | 2000 | 1.00 | 0.1 | 140 | 0.0330 | 60x36x14 | ATD1258N |

|

| T1259N | 1258 | 200-600 | 20 | 2000 | 1.00 | 0.1 | 140 | 0.0330 | 57x36x26 | ATD1259N |

|

| T1321N | 1320 | 4800-5200 | 26 | 3380 | 1.12 | 0.416 | 120 | 0.0107 | 120x75x35 | ATD1321N |

|

| T1401N | 1600 | 3800-4400 | 32 | 5100 | 1.29 | 0.33 | 120 | 0.0096 | 120x75x35 | ATD1401N |

|

| T1500N | 1500 | 1200-1800 | 30 | 4500 | 0.90 | 0.15 | 125 | 0.0184 | 74x50x26 | ATD1500N |

|

| T1509N | 1500 | 1200-1800 | 30 | 4500 | 0.90 | 0.15 | 125 | 0.0184 | 75x48x26 | ATD1509N |

|

| T1589N | 1584 | 2000-2800 | 28 | 3920 | 1.05 | 0.21 | 125 | 0.0135 | 110x75x26 | ATD1589N |

|

| T1601N | 1600 | 2800-3600 | 36 | 6500 | 1.07 | 0.258 | 120 | 0.0107 | 120x75x35 | ATD1601N |

|

| T1929N | 1930 | 3000-3800 | 37 | 6850 | 1.08 | 0.2 | 125 | 0.0092 | 110x75x26 | ATD1929N |

|

| T1989N | 1990 | 1200-1800 | 36 | 6480 | 0.90 | 0.12 | 125 | 0.0135 | 110x75x26 | ATD1989N |

|

| T2101N | 2100 | 2000-2600 | 42 | 8820 | 1.07 | 0.136 | 125 | 0.0107 | 120x75x35 | ATD2101N |

|

| T2159N | 2159 | 2000-2800 | 40 | 8000 | 1.05 | 0.154 | 125 | 0.0102 | 110x75x26 | ATD2159N |

|

| T2301N | 2З00 | 4800-5200 | 49 | 12000 | 1.16 | 0.222 | 120 | 0.0064 | 150x100x35 | ATD2З01N |

|

| T2451N | 2450 | 3600-4200 | 57 | 16000 | 1.17 | 0.176 | 120 | 0.0064 | 150x100x35 | ATD2451N |

|

| T2551N | 2550 | 1200-1800 | 57 | 13000 | 0.90 | 0.089 | 125 | 0.0107 | 120x75x35 | ATD2551N |

|

| T2601N | 2601 | 4800-5200 | 57 | 16000 | 1.13 | 0.18 | 120 | 0.0059 | 150x100x35 | ATD2601N |

|

| T3401N | 3550 | 3100-3600 | 75 | 28000 | 0.82 | 0.145 | 125 | 0.0054 | 150x100x35 | ATD3401N |

|

Part Numbering Guide for Phase Control Thyristors:

| A | TD | 1200 | N | 18 | T | O | F |

| A | – | |

| TD | – | Product group: Thyristor Disc. |

| 1200 | – | Average on-state current IT(AV), Amp. |

| N | – | Phase control device. |

| 18 | – | Voltage class VRRM / 100. |

| T | – | Housing (package) type: disc housing. |

| O | – | Turn off time tq: no guaranteed. |

| F | – | dv/dt class: С: 500 V/μs F: 1000 V/μs H: 2000 V/μs |

High Power Semiconductors AS ENERGITM

Our company is engaged in the manufacturer and sale of wide range of power semiconductors (power thyristors, modules, rectifier diodes, avalanche, rotor and welding diodes, triacs etc.) currents up to 15000A and voltages to 9000V, and air and water heatsinks to them.

You can buy semiconductor devices in any volumes, and when ordering large lots, the price will be lower. We have earned the trust of customers and supply products all over the world.

For questions regarding the acquisition of Power Thyristors, Diodes, Modules send an email request to:

And we will provide you a commercial offer for delivery.

For a large number, we will provide an individual price!!!

We are open to manufacture products at our production facilities

according to your requests and technical task.

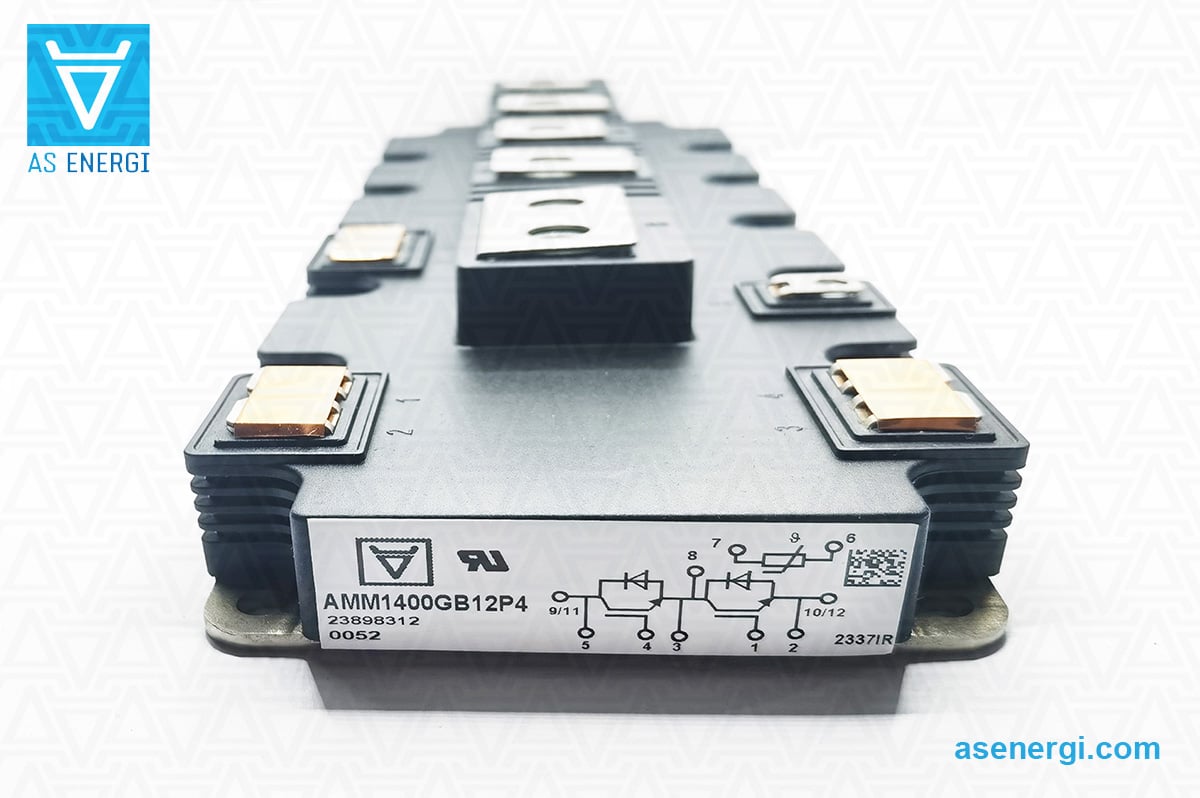

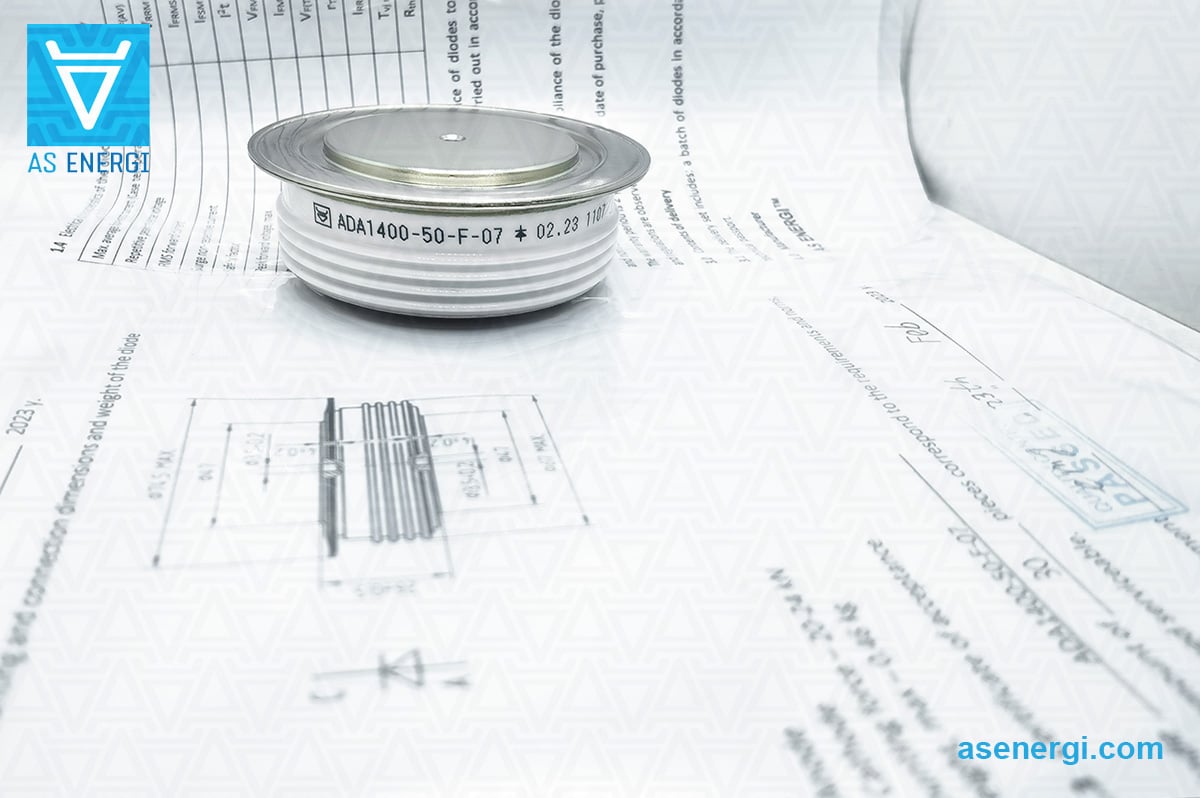

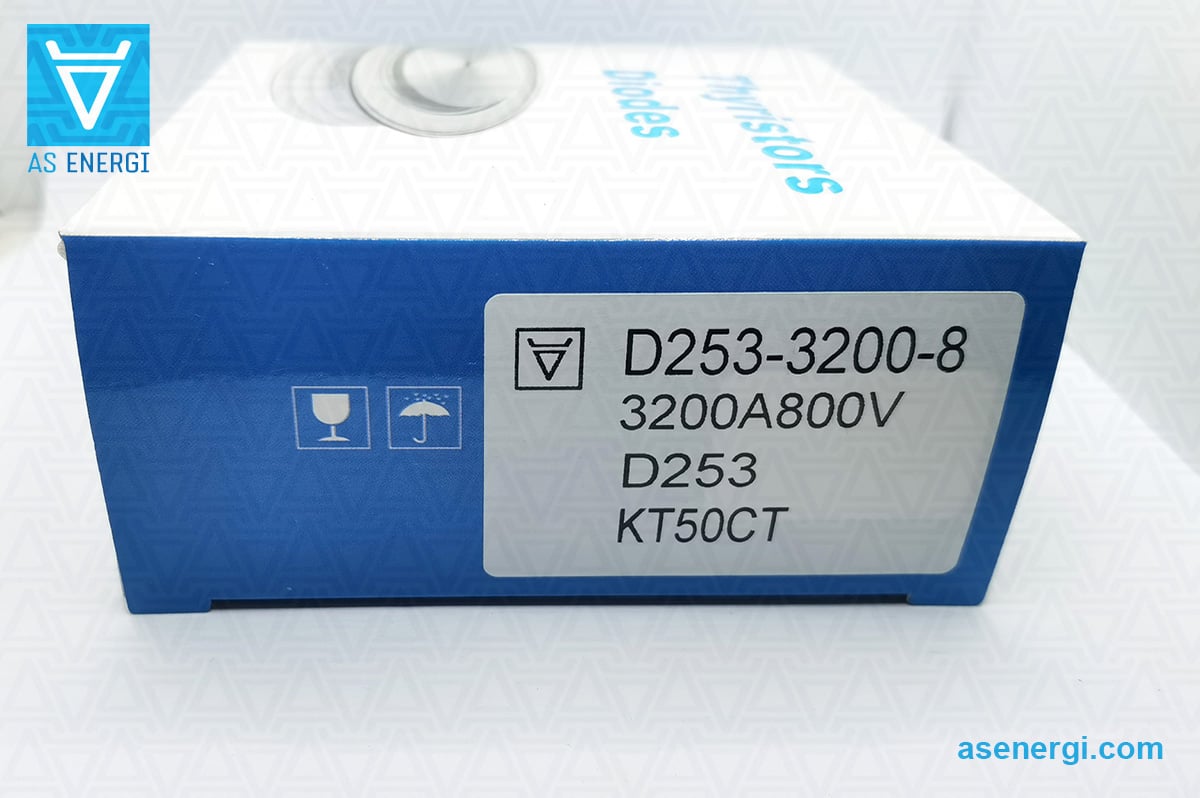

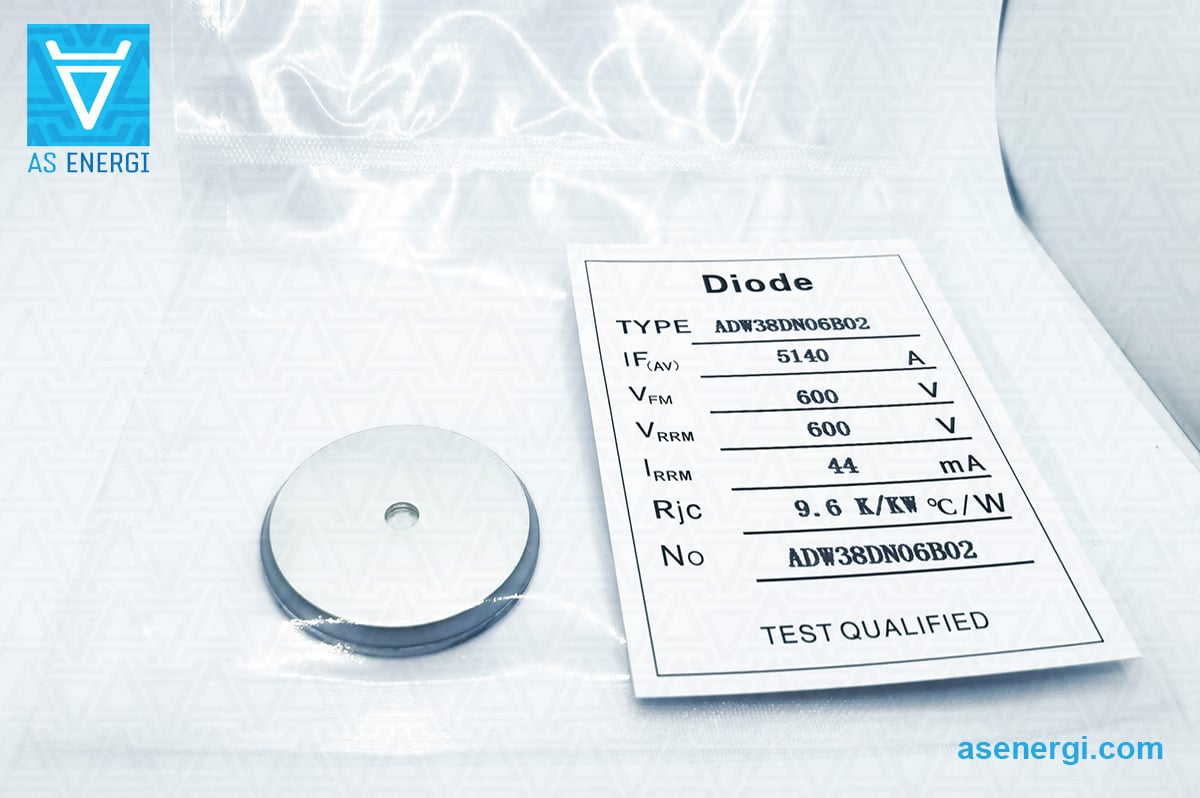

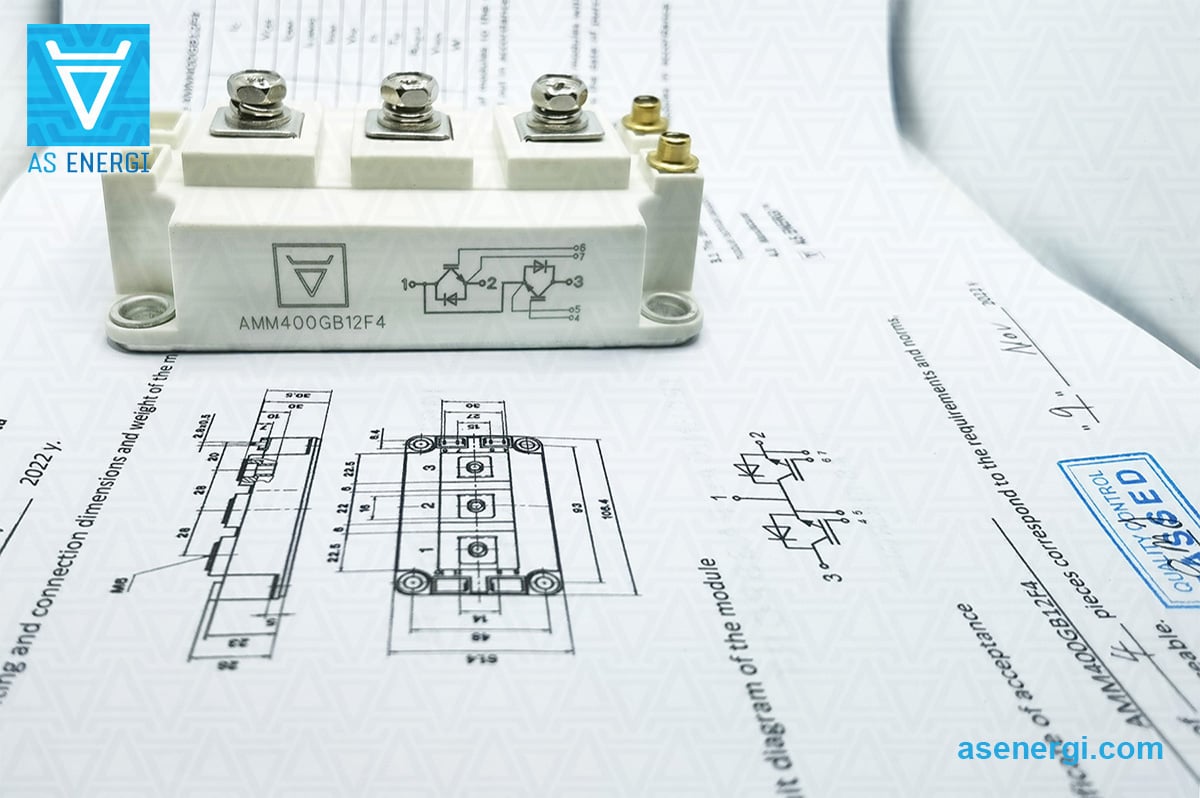

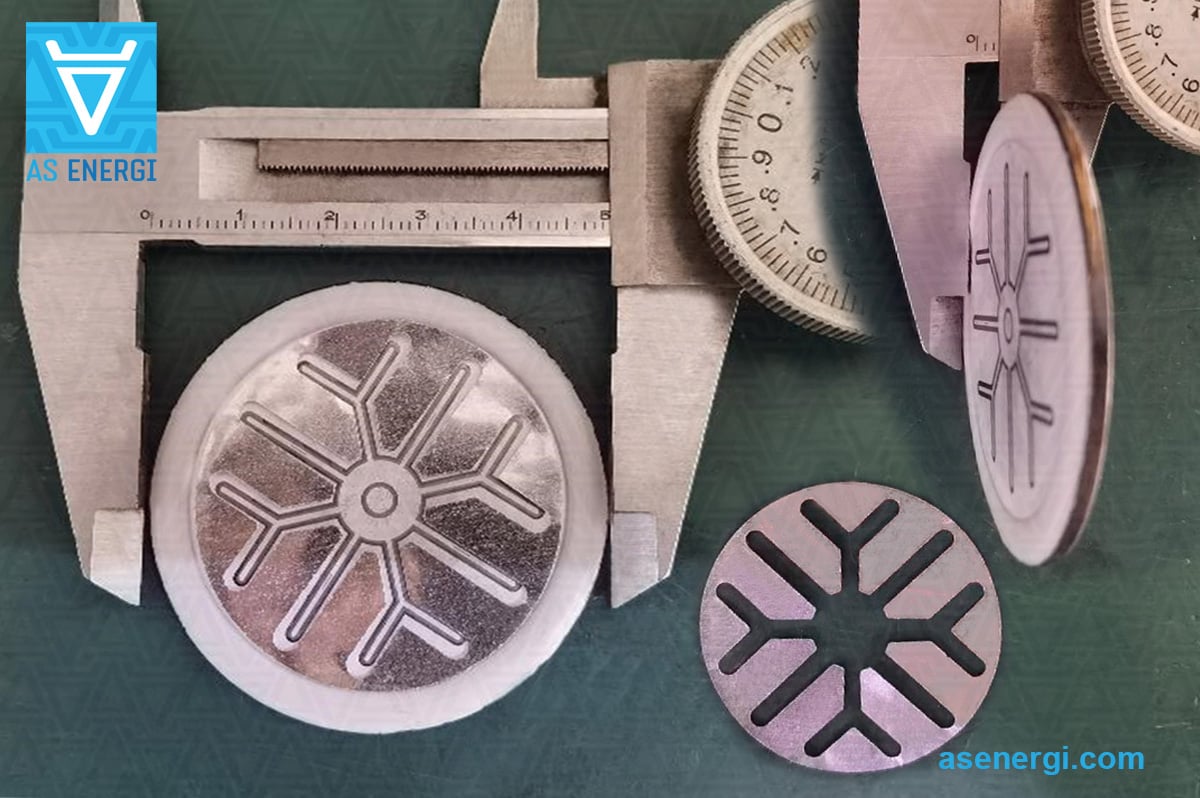

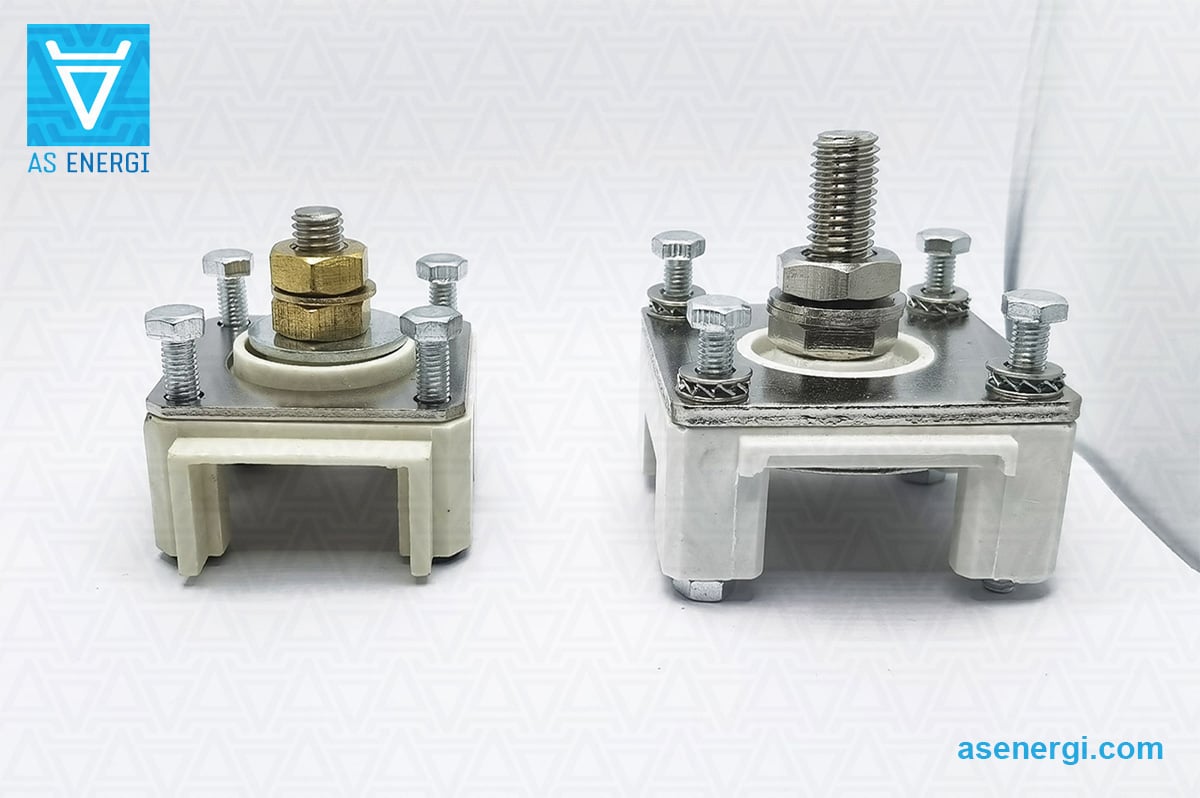

Photo Gallery

The photo gallery shows many different semiconductor devices, semiconductor chips and SCRs produced by AS ENERGITM, examples of test reports.

Installation recommendations for power thyristors:

The reliability of heat transfer and electrical contact between the mating surfaces of the thyristor and the cooler over the entire temperature range is ensured by appropriate torque (clamping force).

Before assembly you should perform visual inspection (1) contact surfaces for mechanical damages and wipe (2), soaked with alcohol (toluene, gasoline, acetone).

After inspection, fix the current contacts (leads), install a pin to fix the alignment of the structure.

To improve the parameters of heat transfer it is recommended to lubricate (3) a thin layer of silicone thermal conductive paste before the assembly, which is not a mandatory condition for installation.

Install the thyristor (3), the second part of the cooler, the fiberglass insulator and the thrust washer.

To thread the traverse (4) and evenly tighten the nuts. Make sure no misalignment and evenness of the contact surfaces.

When the parts are sufficiently clamped but moveable, we recommend placing the cooler on a flat surface and checking the tolerance for parallelism of the overall adjacent plane of the surfaces (5).

Clamp each nut in turn (about a quarter turn) to the stop (6). The amount of deflection of the traverse determines whether the achieved clamping force corresponds to the required one.

After installation, the fasteners (nuts and washers) must be additionally secured against corrosion.

Tips and recommendations for power thyristors:

The power thyristors should not be operated for long periods of time at their limit load for all parameters. In this case, the safety factor is determined by the required degree of reliability of the device.

Replace a failed power thyristor with a thyristor that matches the parameters of the one being replaced.

Supercooling must be provided when operating in an environment with an elevated ambient temperature.

Periodic cleaning of power thyristors and coolers to remove dust and contaminants is recommended to ensure proper heat dissipation.

Inductive current dividers (often twisted toroidal wire) should be used to equalize currents between power thyristors connected in parallel. The most popular connection methods are closed circuit, common coil circuit, or power thyristor. The efficiency of current dividers in this case is determined by the cross section of the magnetic wire.

Prevention of voltage unbalance when power thyristors are connected in series is achieved by using shunt resistors connected in parallel with each thyristor. Voltage equalization in transient conditions is provided by connecting capacitors in parallel to each thyristor.

It is strictly forbidden to touch power thyristors under high voltage during operation.

Why choose AS ENERGITM

Why choose AS ENERGITM

- Own production facilities, including semiconductor silicon chips production

- European brand - 100% quality, favorable price, short production terms

- Over 20 years of experience in the semiconductor industry

- Clients from more than 50 countries trust us

- 20000 items in the product line for currents from 10A to 15000A, voltages from 100V to 9000V

- We produce analogues of other manufacturers' products

- Guaranteed certified quality, warranty period of operation - 2 years

Quality Warranty

Our products are certified and correspond to international standards.

Our company provides a quality guarantee for products of 2 years.

We provide certificates of conformity, reliability reports, data sheets and technical passports at the request of the customer.

Each product is tested for the main parameters, and Test reports of the parameters for each product are provided.

Geography of partnership

AS ENERGITM company manufactures and supplies power semiconductors to more than 50 countries around the world.

Logistics and Delivery

We deliver our products all over the world with the services of logistics companies: DHL, TNT, UPS, EMS, Fedex, Aramex.

Products can be delivered by any means of transport: air, sea, rail and road.

AS ENERGITM Semiconductors Manufacturing

Our products range includes rectifier diodes, phase control thyristors in disc and stud design, avalanche diodes and thyristors, fast switching, high frequency thyristors, fast recovery, welding and rotor diodes, triacs, bridge rectifiers, power modules (thyristor, diode, thyristor-diode, IGBT), and air and water heatsinks to them.

Power diodes and thyristors are produced for currents from 10A to 15000A, voltage range from 100V to 9000V.

Power diode and thyristor modules are produced from 25A and up to 1250A, voltage range 400V - 4400V.

The range of power semiconductors also includes equivalent, replacement, analogue and alternative semiconductor devices of global manufacturers.

Featured Products:

DE

DE IT

IT